Sand is a crucial building material in construction, used for making concrete, mortar, plaster, and other foundational components. Its properties, such as texture, grain size, and composition, determine its suitability for different construction tasks.

Understanding the types of sand and their specific applications can help ensure the durability and stability of a structure. In this article, we’ll explore seven types of sand commonly used in construction, their characteristics, and their ideal uses to guide you in selecting the right sand for your projects.

- Concrete sand

- Pit sand

- Natural sand or river sand

- M-sand

- Utility sand

- Fill sand

Here are The Details of Different Types of Sand!

1. Concrete Sand

Concrete sand is made of crushed concrete and is used in asphalt and cement mixtures. While manufacturing concrete sand, concrete is crushed in the quarry before filtering to remove large fragments and huge rocks. Concrete sand is mixed with water and cement to form a solid mass that is used as a levelling base for walking paths, patios, and layers. This solid mass is also used to fill the voids in coarse aggregates.

It has comparatively smaller grains making it suitable for creating pavements. Its grains are, however, larger than the white sand so it can be used as filling material too. The texture and size of concrete sand are ideal for several applications that provide fundamental stability to a structure.

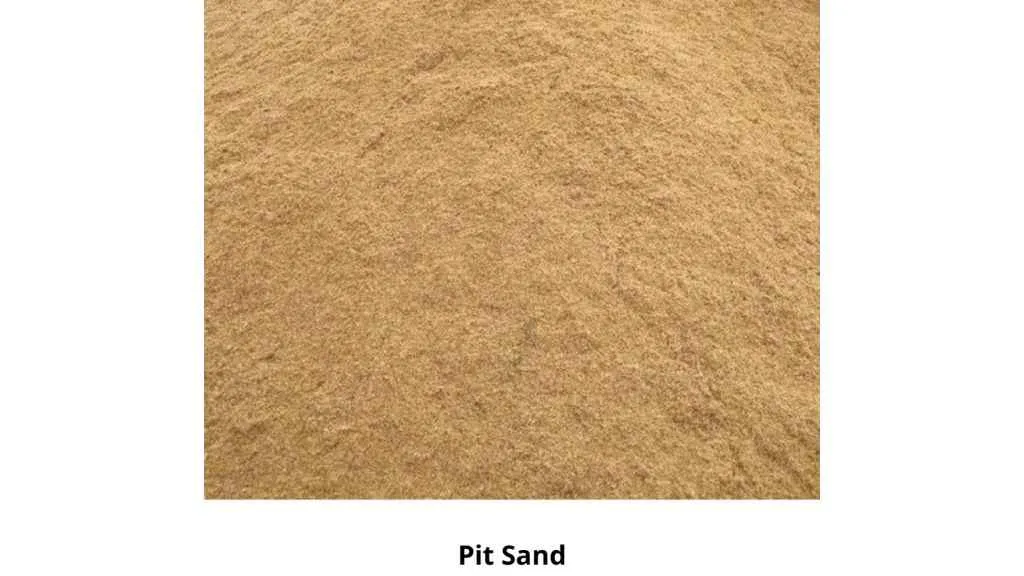

2. Pit Sand

The type of sand found 2 to 3 meters below the surface level in deep pits is called pit sand. Their superior binding property makes it an ideal component for construction. It consists of coarse, angular, sharp, and rough grains which provide the amazing binding feature of the sand.

They are orangish-red in colour because of iron oxides. The sand is free from salts so they do not absorb atmospheric moisture easily. Since there is no moisture in the sand, they provide compelling rigidity and strength to the building.

3. Natural or River Sand

River sand is gathered from the banks of streams and rivers. They are fine in quality and greyish white coloured. One of the finest sands, river sands are mainly used in masonry and concrete construction but also find their application in building blocks, bricks, plastering, and RCC.

The sand has a smooth texture and requires less water because of the more refined grains. River sands have moisture trapped in between their grains. Typically, a medium-quality type of river sand consists of 5% to 20% silt.

Since river sand can be obtained naturally, it is way cheaper than other types of sand. The presence of silica (below 5%) in them makes them ideal for construction work.

4. M-sand or Artificial Sand

This type of sand is manufactured in factories and is used as a substitute for river sand in the construction of concrete. Ever since the demand for quality grade sand has increased, manufactured sand has been used in construction.

M-sand is manufactured by crushing hard granite rocks which saves the transportation cost involved in bringing river sand from the river banks to the construction site. It contains grains with an angular shape that strengthens the concrete. Angular grains demand water content which is compensated by adding cement to the sand.

Since M-sand is artificially manufactured, it contains no silt or oversized materials typically found in construction materials. It is also free from several impurities and can be control-produced, i.e. The size of the grains can be predetermined to suit individual purposes. The quality can be controlled to provide durability and strength to the concrete. It is quite economical and there will be no defects in construction when M-sand is used.

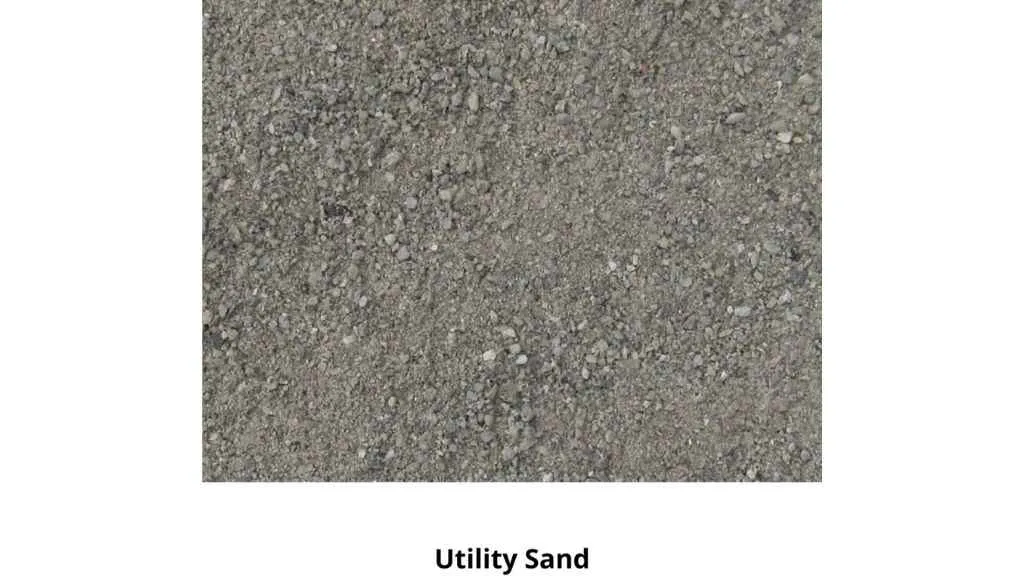

5. Utility Sand

The type of sand produced from industrial quartz is called utility sand. Utility sand comes with excellent mechanical properties and compaction because of the uniform shape of its grains. It finds its purpose in corrosive environments due to its non-reactive nature. With 100% natural minerals in them, utility sand provides high stability and durability to the structure.

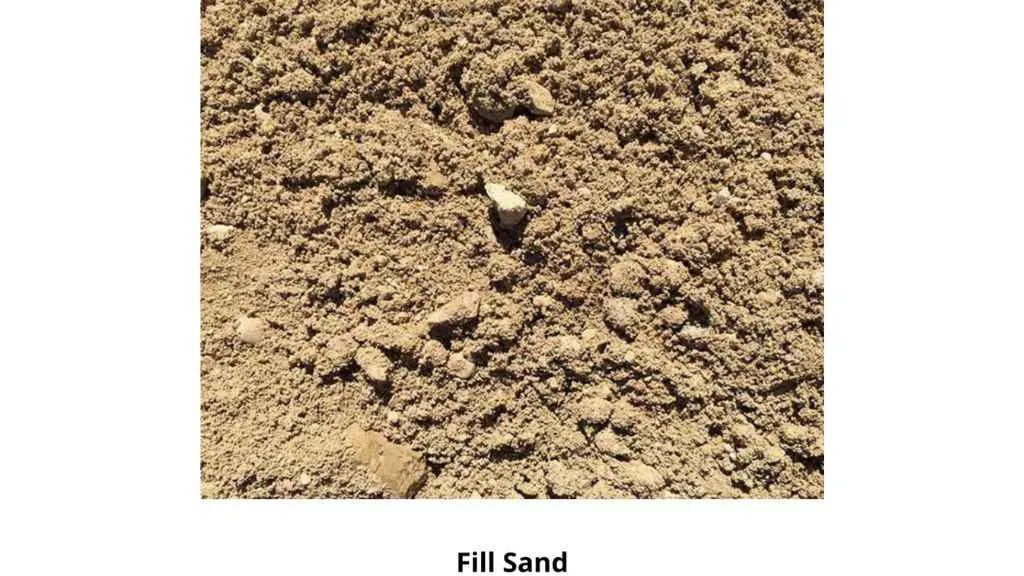

6. Fill Sand

Fill sand, as the name suggests, is used for filling. It is a combination of aggregates (very fine eroded rock particles) and sand grains. Fill sand is primarily used as a base for filling large holes, paving, and laying concrete. It provides excellent compaction and is at an advantage in wet areas (It serves as a backfill around septic tanks).

7. Artificially Made Sand

Sand that is artificially produced, known as manufactured sand, presents a more environmentally friendly option compared to river sand. This type of sand is typically derived from crushing granite in plants or factories, aiming to offer an eco-friendly and cost-effective substitute for natural sand.

The process involves blasting and crushing quarry stones and boulders, followed by multiple crushing stages to reduce particle sizes. Subsequently, the sand undergoes sieving and washing to remove contaminants and fine particles.

The quality of the manufactured sand is assessed to ensure its suitability as a construction aggregate. The Screed Scientist suggests that manufactured sand should easily pass through a 3/8 sieve after production, making it ready for use in construction projects.

Tests for Assessing Sand Properties

Evaluating sand properties involves a series of tests:

- Detection of Organic Contaminants: Introduce a mixture of caustic soda or sodium hydroxide to the sand, agitating it to unveil any organic materials. The indication of the presence of such substances manifests through a color shift, transitioning from the normal hue to a brownish tone.

- Examination of Clay Content: In the quest to identify clay, conduct a test using a glass jar filled with a sand and water combination. Vigorously mix the contents and allow them to settle. The observation of a distinctive layer forming atop the sand indicates the presence of clay, which diminishes the sand’s binding qualities.

- Identification of Salt: To discern salt content in the sand, taste a sample after a thorough wash. The most effective approach is to assess the flavor on the tip of the tongue. A salty taste confirms the presence of salt in the sand.

What Purpose Does Sand Serve in Mortar and Concrete?

- Boosting Mortar Size: Even though it doesn’t directly make mortar stronger, adding sand is essential. It makes the mortar take up more space, so you don’t need as many other ingredients.

- Stopping Cracks: When sand is in the mix, mortar doesn’t shrink too much when it dries. This helps prevent cracks from forming as the mortar settles.

- Breaking Down Paste: Sand breaks down the sticky part (paste) into a thin layer, making it easier to spread and stick.

- Filling Things Up: Acting like a filler, sand makes concrete take up more space. Less air in it makes the final product stronger.

The Bottom Line: What are Some Other Types of Sand?

Sands are classified based on where they are available, their applications, their properties, and their colour. Apart from the 6 different types of sand mentioned in the article above, there are some other types of sand too. They are

- Gravelly sand

- Coarse sand

- Fine sand

- Plaster sand

- Brick sand

- Sea sand

- Heavy mineral sand

- Volcanic sand, etc.

There are a few deciding factors when choosing the type of sand for construction. The sand should:

- Not contain impurities

- Be free from organic materials

- Contain less than 3% silt

Types of Sand FAQs:

1. What are the most common types of sand?

2. Which is the finest sand?

3. Which is the best sand for construction?

4. What type of sand is found on beaches?

5. What is standard sand?

6. What are the different types of sand dunes?

1.Parabolic

2. Dome

3. Star

4. Linear

5. Crescentic

7. How many types of sand are there?

1. Concrete sand

2. Pit sand

3. Natural sand or river sand

4. M-sand

5. Utility sand

6. Fill sand

7. Gravelly sand

8. Coarse sand

9. Fine sand

10. Plaster sand

11. Brick sand

12. Sea sand

13. Heavy mineral sand, etc