A lintel, meaning a structural part that rests across openings like windows, doors, etc., carries the load of the structure above it. The main purpose of the lintel beam is to support the loads originating from above the wall and pass such loads to the side walls. These beams are made of various materials and are rectangular in plan and section. The ends of a lintel beam are constructed into the wall, and the width of the beam and the width of the wall are equal.

How Big is a Lintel Beam?

Between 1/12 and 1/8 of the span, the width of the lintel can be equal to the depth and thickness of the opening. The width of a lintel beam should be at least 4 inches (100 mm).

Why is a Lintel Beam Used in Construction: Advantages of a Lintel Beam

The following is a list of some of the main strengths of using lintel beams in construction:

- They are easy to assemble and construct.

- Because the excessive load is not imposed over the lintels’ ending supports, they need not be built with much strength.

- They look quite simple and fragile.

- The lintel may be easily centred, and the framework is reasonably priced.

Now comes the purpose of lintel beams in buildings:

These beams are used to prevent the walls above windows and doors from damage. By support we mean, the lintel beams withstand the loads exerted by the bricks or blocks above them by diverting the load onto the side walls. The lintel beam is also used as an occasional decorative element in architecture.

7 Types of Lintel Beams

1. Wooden Lintel

The oldest type of lintel is made of wood, however, it is no longer utilized in construction. Since wood is the primary building material used to construct homes globally, they use wood chunks as lintels. A lintel can be made of a single piece of wood or a collection of wooden pieces joined by bolts.

Specifications of Wooden Lintel Beams

- It is recommended to set a bearing of 150 to 200 millimetres before placing a wooden lintel on the mortar.

- The lintel’s width could be equal to the depth and thickness of the opening but within a range of l/12 and of the span.

- There should be a minimum width of 80mm available.

- Fire and rot can readily ruin the wooden lintels.

2. Stone Lintels

Because it is a readily available material, stone lintels were always used to span the opening. The strong compressive strength of stone lintels makes them a popular building material.

Specifications of Stone Lintel Beams

- Since rocks have poor tensile resistance, relief arches should be created while being used as a lintel.

- A lintel can be made from a single piece of stone.

- The lintel’s breadth ought to match the opening’s thickness.

- The stone lintel’s depth should be between 1/10 and the length of the entrance.

3. Brick Lintels

Brick lintels are intended to cross narrow openings with minimal loading. Bricks are typically set on their ends, though occasionally they are laid on their edges, to make up brick lintels. The brick lintel is built above a turning piece, which serves as a temporary wood support.

Specifications of Brick Lintel Beams

- The brick lintel won’t technically have very good resistance to the compressive load.

- Therefore, these lintel types should be used only when the opening length is less than 1m.

- The brick lintel should be at least 20 cm deep, and as is customary, its breadth should match the thickness of the entrance.

4. Reinforced Concrete Lintels

RCC lintels have now supplanted all other lintel materials because they are fire-proof, long-lasting, dependable, and simple to construct. The fact that the RCC lintel can be installed either cast-in-situ or precast is a great advantage. Precast lintels are intended for spans up to 2 metres. On the other hand, if the opening length is greater than 2 metres, the lintel will be built using the cast-in-situ process.

Specifications of RCC Lintel Beams

- Lintel concrete is often made with M15 (1:2:4) concrete grade.

- Because sunshades may easily protrude from RCC lintels, they can improve building activity.

- The span of the opening determines the depth and reinforcement.

5. Steel Lintels

Rolled joists or steel angles are part of the steel lintels. The former is used for heavy loading and large spans while the latter is used for light loading and small spans. The joists are held in place by tube separators that are provided. To shield the steel from rust and fire, the steel joists are set inside the concrete.

Specifications for Steel Lintel Beams

- Steel lintels should comply with ASTM A 36.

- Their angle should be at least 6 mm in thickness (i.e., ¼ inches).

- It should have a horizontal leg of at least 90 mm (i.e., 3 ½ inches) if it’s supposed to be used with a nominal 4 inches.

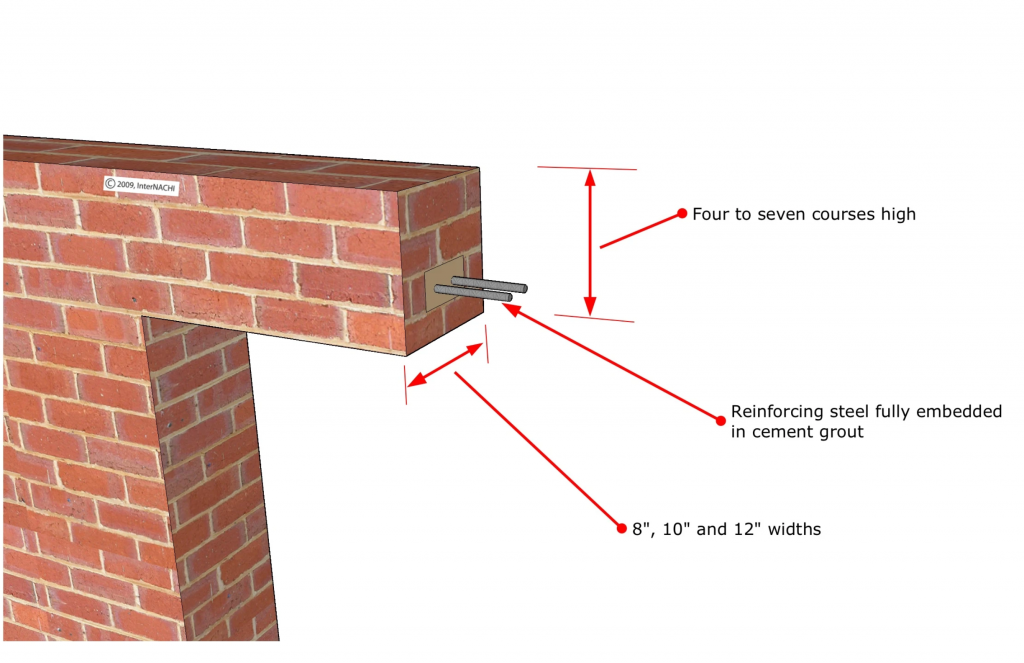

6. Reinforced Brick Lintels

Brick lintels are built quite similarly to R.C.C. brick lintels, with the exception that here high-quality brickwork is used in place of concrete. RCC brick lintels are strengthened with steel bars in the event that they are to be used for bigger spans.

Specifications of RCC Brick Lintel Beams

- When using bars as reinforcement, the bricks are laid in parallel rows.

- This ensures that there is space lengthwise that is 2-4 cm wide for the street bars or rods to be inserted.

- The cement concrete or cement mortar is poured into the gap after the steel rods or bars are in place.

7. Precast Lintels

When using precast lintels the hangar bars and top reinforcements can be neglected for one-span members with a light load. All the flexural stresses are taken up by the reinforcements provided ta the bottom of precast lintels. This saves the cost of formwork and labour.

Specifications of Precast Lintel Beams

- The width of a precast lintel beam must be equal to the wall width.

- The depth should be a minimum of 100 mm while the length depends on the opening span.

- 15 MPa is the minimum concrete grade that must be used to construct them.

- Precast lintel beams can be reinforced with 12mm diameter bars (3Y12 or 2Y12).

- The minimum reinforcement area must be 0.13% of the total cross-sectional area.

A Final Word on Lintel Beams

According to the Merriam-Webster dictionary, a lintel is a load-bearing element that is positioned over an entranceway in classical Western construction and architecture techniques. The lintel, also known as an architrave, is a structural component that typically supports a portal or entranceway and is supported by stone pillars or stacked stone columns.

A lintel can also cross the width of a route or road to create a stone lintel bridge or support the chimney above a fireplace. The carved stone lintels’ non-load-bearing design allowed for inventive aesthetic applications of traditional Buddhist motifs in ancient Indian architecture.

In medical applications, lintels may also be employed to lessen dispersed radiation. For instance, high-energy medical linacs will emit active neutrons that will scatter outside the treatment bunker area at a dose rate dependent on the cross-section of the maze. Lintels in the facility’s roof may be visible or recessed, and they can lower the dose rate in the publicly accessible sections by narrowing the cross-section of the maze.

Now, that’s an amazing use of lintel beams!

About lintel FAQs:

1. Is a lintel beam necessary?

When openings like doors, windows, etc. are required to create a building structure, a lintel is one form of a beam that is utilized to support the above wall. The main purpose of the lintel is to transfer weights from above the wall to the side walls.

2. What is the size of the lintel?

There are two types of box lintels, one that can support 100mm wide walls and the other that support 200mm to 215mm walls. Here’s how the lintel levels for these two walls vary:

3. What is the difference between a lintel and a beam?

The beam bears the weight and transfers it from the slab to the column, then the column to the footing, and lastly from the footing to the soil. In contrast, the lintel transfers the weight of the wall above the openings to the walls alone.

4.What is the maximum span for a lintel?

Lintel beams must be propped at no more than 1.2m intervals until the brickwork or concrete above it has fully developed. To add more to it, between l/12 and l/8 of the span, the width of the lintel could be equal to the depth and thickness of the opening. There should be a minimum width of 80mm available.

5. How is the lintel beam calculated?

The length of the lintel in a brick wall is determined by measuring the opening’s overall width and adding 150 mm for end bearings at each end. In a house, a door or window’s soffit level corresponds to the level of the lintel

6. Can we remove the lintel beams?

The only horizontal frames that withstand vibrations are the lintels in a structure. If we remove the lintel and install a steel beam individually at the roof level, this won’t exist.

7. Can I drill into a lintel?

Start with the shortest drill bit for masonry in your set for drilling into a concrete lintel. The size of the hole you require can be obtained by working your way up from a drill bit of 3mm. The smaller the drill bit, the easier it will be to drill through concrete.

8. Is the lintel horizontal or vertical?

A lintel is a horizontal support that spans between two vertical supports or an entrance in a wall. It is typically utilised over doors and windows, two areas of a building’s structure that are particularly vulnerable.

9. How do you calculate lintel load?

The load ratio is ordinarily 1:1 when the lintel is supporting just the masonry. For lintels supporting loads from a timber floor, this typically increases to 3:1 (inner to outer leaf), and when a concrete floor is used, it climbs to 5:1. The load ratio for eaves applications is 19:1.

10. Does every door need a lintel?

You might not need to install any additional lintels if the building has enough support where the door is located. However, as a result of current building regulations, they are now necessary. Lintels are required for all openings with steel frames wider than 900 mm and all openings with timber frames wider than 600 mm.