Planning a construction project but overwhelmed by the wide variety of building materials available? Choosing the wrong materials or missing out on essentials can lead to structural issues and increased costs.

From laying the foundation to the final finish, understanding the purpose and application of each material is crucial for a successful build. This article provides a comprehensive list of 17 essential building materials, detailing their uses and importance, ensuring your construction project is durable, efficient, and aesthetically pleasing.

Here are the 17 items list from a typical materials used in construction projects and we’ll study each one of them:

- Aggregates

- Cement

- Clay Bricks and Blocks

- Fabric

- Fired Brick and Clay Blocks

- Foam

- Glass

- Gypcrete

- Metal and Steel

- Mud and Clay

- Sand

- Stone or Rock

- Wood and Timber

- Thatch

- Plastic

- Steel

- Bitumen

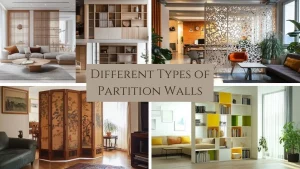

List of Building Materials Used Construction

Now let us take a look at the most common building construction materials list.

1. Aggregates

Aggregates can be used for a variety of purposes as raw materials, while particular jobs may necessitate the usage of a certain kind of aggregate. Concrete contains a significant amount of aggregate and cement. As a construction material, aggregates are used to provide drainage, fill gaps, protect pipelines, as well as provide hard surfaces. Aggregates are not as impacted by the weather as soils, especially clay soils, and will not split due to shrinkage during dry seasons.

Properties

- The size and form of aggregate particles have a greater impact on the characteristics of newly mixed concrete than on hardened cement paste.

- Maximum bond strength arises when the surface is coarse but porous. The binding strength of porous surface aggregates rises as the cement paste sets in the pores.

- Low specific gravity denotes porous, weak, and absorptive materials, while high specific gravity (2.6 to 2.9) denotes high-quality materials.

- The bulk density of aggregates is determined by three factors: degree of compaction, aggregate grading, and aggregate particle shape.

- Fine aggregate has a significantly larger specific surface area than coarse aggregate.

Application

- Aggregate is utilized in a variety of constructions and substructures, including building components, bridges, and foundations.

- This building material is also used on roadways to help spread the weight and keep groundwater off the road.

- An extremely resistant aggregate is required not only to hold the enormous weight of trains but also to distribute and transmit it effectively to the ground to minimize damage to the rails, ground, and other surrounding buildings.

2. Cement

A cement is a building binder that sets, hardens, and clings to other materials in order to bond them together. It’s more commonly used to mix sand and gravel together. Companies that create cement use it with fine aggregate to form mortar for construction, or sand and gravel to build concrete.

There are many types of cement, but the most common ones are:

- Ordinary Portland Cement (OPC)

- Portland Pozzolana Cement (PPC)

- Quick Setting Cement

- Low Heat Cement

- Rapid Hardening Cement

- GGBS (Ground-granulated blast-furnace slag) Cement

Properties

- When water is added to fibre cement, the increased specific surface area aids in increasing the rate of hydration, resulting in earlier and better strength development.

- Cement pre-hydration reduces the strength of the cement and affects the setting time. The strength, porosity, pore size distribution, and chemistry of cement paste/concrete/mortar are all affected by carbonation.

- Cement has a bulk density of 1000 to 1300 kg/m3.

Application

- Can be used for plaster and brickwork as mortar, by mixing cement with sand

- Can be used for lab, columns, footing, beam as concrete, by mixing cement with sand and aggregates

- Can be used for tile works as slurry

- Can be used for repairing purposes such as paste

3. Clay Bricks and Blocks

Bricks are made by burning clay at high temperatures. The heat fuses the clay particles together, forming a strong ceramic bond. These bricks are long-lasting and are composed of clay, sand, lime, magnesia, and iron oxide.

The term clay blocks have become popular in the construction business. Due to the vertical or horizontal hole and properly packed insulating material, they are also known as Porotherm bricks or Perforated bricks. They are composed of clay, coal ash, fly ash, rice husk ash, and sawdust.

Properties

- Clay bricks and blocks have 20% and 15% water absorption capacity respectively

- Clay bricks and blocks have 1700 to 1920 kg/m3 and 694 and 788 kg/m3 respectively

- Clay bricks and blocks have 7.5 to 10 N/mm2 and 3.5 N/mm2 respectively

Application

- Walls, pathways, sidewalks, lanes, pathways, and landscaping are all common uses for clay bricks.

- Hollow clay bricks are utilized in both the interior and exterior walls of a structure, but only up to the fourth storied structure.

- Hollow bricks are occasionally used to build partition walls.

4. Fabric

In civil engineering, the fabric is used in many different places, but at the moment it is used to create a fabric framework that allows consumers a variety of appealing free-form architectural styles. For increased tensile strength, endurance, and environmental resistance in the fabric structure, inorganic components are laminated and coated onto the fabric.

Properties

- They are fire-resistant.

- They are also resistant to weather changes.

- Natural pressures also have no effect on them.

Application

- Wind, rain, solar radiation, snow, and other elements of the weather should be protected from the building’s inhabitants.

- Assist inhabitants in maintaining their privacy.

- Temperature, humidity, wetness, and other aspects of the interior environment may all be controlled.

- Noise transmission should be avoided.

- As an example, provide safety by stopping the spread of fire or smoke.

- Ensure the safety of the building’s residents and their belongings.

- Allow access from both the interior and outside of the building.

- Allow for both inside and outside views of the structure.

5. Fired Brick and Clay Blocks

The traditional kind of brick is burned clay brick. These are made with wet clay and pressed into moulds, and finally dried and fired in kilns. This is among the earliest old construction materials that may be found in many of the world’s ancient structures. These bricks look to be solid chunks of solidified clay that are generally reddish in colour.

Plastering with mortar is required when burned clay bricks are used in walls. Burnt clay bricks can be used to build masonry walls, foundations, and columns.

Fired clay bricks are of three types:

- Basic fire bricks

- Neutral fire bricks

- Acidic fire bricks

Properties

- Fire bricks have a compressive strength of 200 to 220 Kg/cm2.

- The proportion of water absorbed ranges between 5 and 10%.

- They are chemically resistant.

Application

- Pavements

- Facades

- Open spaces

- Driveways

- Furnace lining

- Utensils manufacturing equipment

6. Foam

Foam concrete is a form of light concrete that offers a number of advantages over traditional building materials, including low density and heat resistance. It also offers equal dispersion of air bubbles in the concrete.

A foam concentration is generally used to make foam blocks. It combines the benefits of stone and wood: durability, lightweight, thermal insulation, and no requirement for additional building materials to be compatible.

Properties

- Lightweight

- Flexible

- Durable material

- Provides thermal insulation

Application

- Among the long building construction materials list, foam is utilized as an insulator between wood, cement, or insulation concrete foam

7. Glass

Glass is one of the earliest and most versatile construction materials available. Since its discovery, glass has been utilised to enhance the attractive appearance of structures and has been a remarkable material.

Glass is an inorganic, transparent, or translucent material that can be shaped into any shape. It is an open hard solid made by heating sand or quartz.

Various types of glass are used as construction materials nowadays, and here’s a list of them:

- Chromatic glass

- Float glass

- Double glazed glass

- Extra clean glass

- Glass blocks

- Glass wool

- Laminated glass

- Shatterproof glass

- Tinted glass

- Toughened glass

Properties

- Glass is normally fragile and readily breaks, but by adding admixtures and laminates, we may make it stronger.

- Any variety of glass may be utilised as a raw material in buildings and is 100 percent recyclable.

- The U value of insulated glass units is low, which makes them heat-insulating.

Application

- Curtain walls and balconies

- Glass Railings on the stairwell and balcony.

- Cubicles in the bathroom

- Partitioning between the office and the home

- Furniture for the office/home, etc.

- Terrariums

- Glass doors with no frames

8. Gypcrete

Gypcrete or gypsum concrete is a combination of cementitious and filler elements. Sand, Portland cement, and gypsum plaster are mixed in a certain proportion.

One of the most significant advantages of gypcrete is its small weight, which makes it very easy to work with. It’s a common subflooring solution for carpets and other epoxy floorings. Even so, it’s advisable to double-check that the flooring will work with gypcrete.

Properties

- Gypcrete has a weight of roughly 13 pounds per square foot. As a result, lightweight gypcrete is an excellent floor underlayment that is also very easy to work with.

- In homes with floor heating, gypcrete is a preferable alternative for subflooring.

- Gypcrete is sound-absorbing material.

- The most significant advantage of gypcrete is its fire resistance. It provides a one to two-hour fire barrier that not only slows the spread of fire but also allows occupants to flee.

Application

- Gypcrete is the material of choice if you need fire-resistant or soundproof flooring, or if you want radiant heating on the floor. Gypcrete is a type of floor foundation that must be used with certain types of flooring.

9. Metal and Steel

Next to concrete, metal or steel is the second most predominant construction material. It is among the most versatile and durable construction materials available. Steel’s main function is to provide a skeleton for a building or structure, which is essentially the section of the construction that holds everything together.

Properties

- High melting points

- Good conductors of electricity

- Good conductors of heat

- High density

- Malleable

- Ductile

- Assemble a sturdy, rigid framework for the structure

Application

- Roofing, rafters, supporters, interior walls, ceilings, panelling, and external wall insulated panels.

- Steel is also used for inside fixtures and fittings such as rails, shelves, and staircases.

- Steel is used in the construction of bridges, tunnels, rail tracks, and facilities such as gas stations, railroad stations, ports, and airports.

10. Mud and Clay

Ever since the dawn of time, mud has always been the most fundamental of construction materials. Mud has a number of natural qualities that make it potentially valuable all over the world.

Clay is also one of the key components exploited throughout the structure when blended with additional binders and aggregates. Binders, aggregates, and stabilisers are used differently depending on the process.

Properties

- The abundance of mud makes it one of the cheapest alternatives on the construction materials list

- Mud decreases energy consumption directly due to its quantity and ease of supply, as well as the use of less energy-intensive building equipment.

- Soil recycling does not even necessitate the use of any external resources.

- Mud acts as an insulator, preventing outside heat from entering the structure while keeping a cool inside temperature.

Application

- To construct walls, floors, and even roofs, a mixture of mud and water with the inclusion of stone, bitumen, straw, gravel, and lime is typically utilised.

- Stabilised mud has been mixed with a binder such as bitumen or cement. It’s sometimes called mud cement, concrete, or soil cement.

- Mud was commonly used to plaster building walls, construct building walls, and produce mud bricks in the past.

- Mud and clay can also be used to make bricks, plaster, mortar, and concrete.

11. Sand

Sand is a natural loose, broken substance made up of extremely minute particles of decomposing rocks, corals, or shells. Sand adds bulk, strength, and other qualities to structures. It’s also used in landscaping as a decorative element. Glass is made with certain sorts of sand, while metal casting moulds are made with specific types of sand.

Quartz and feldspar particles make up the most prevalent sand.

Properties

- Sharp, angular, and coarse grains

- No clay and organic materials

- Long-lasting minerals

- Devoid of clay and silt coats

- No biological materials in it

Application

- Used as a foundation layer called blinding. It is spread over a layer of foundation to give a smooth, straight, and clean surface for building operations.

- Used as an architectural precast in landscaping in its natural state.

- Used to make glass in liquid form and is also used to create metal castings.

- Used to make sandpaper.

12. Stone or Rock

In building construction material, stones are one of the most significant building materials. Stones have two or more minerals from the earth’s crust and have no specific chemical composition or shape.

A mineral is a material that is created by an inorganic activity and has a certain chemical composition and molecular structure. They are powerful, long-lasting, and attractive.

Properties

- Strong enough to provide strength and durability

- Can be used for cement concrete

Application

- As a foundation material for construction projects, as well as the building of wall surfaces, towers, bridge decks, and reservoirs.

- In regions where it is naturally accessible, in stone masonry.

- In cement concrete, as coarse aggregate.

13. Wood and Timber

Wood is a versatile organic resource that is also the only renewable building material available. Wood is a popular building material due to a variety of desirable characteristics such as low heat conductivity, low bulk density, relatively high strength, and mechanical workability.

Properties

- Heat does not cause a significant expansion in wood.

- Depending on how it’s oriented, wood may either enhance or dampen sound.

- Dry wood is a good electrical insulator and doesn’t collect static energy.

- Wood is a strong and long-lasting material.

- Wood is seen to be warm, rustic, and attractive. It also comes in a wide range of colors, shapes, smells, and textures.

Application

- Softwoods are commonly utilised to produce doors, furniture, and window frames

- Hardwoods are used to build walls, roofs, and flooring

14. Thatch

The process of making a building’s roof out of dried plants like straw, water reed, sedge, rushes, heather, or palm branches is known as thatching. Thatching prevents shaded water from reaching the inner roof and serves as insulation with the help of tightly packed plants.

We have employed this really ancient technique for roofing for a long time. Nowadays, thatch is employed in underdeveloped nations because low-cost dry vegetation is the most wanted ingredient for thatching. In industrialised nations, people employ thatch to elevate buildings or give their homes a rustic appearance.

The roof’s form, design, pitch, location, the quality of the thatching materials used, and the thatcher’s expertise all affect how well the thatching will hold up over time.

Properties

- Thatch is a naturally water-resistant material that, when maintained properly, doesn’t absorb water.

- The roof has a slope of up to 50* to prevent water penetration and allow it to swiftly drain off.

- Thatch has an insulating quality. The straw helps the roof function well both during the winter and summer seasons.

- Additionally, it has high wind damage resistance.

Application

- Thatch is frequently employed as a roofing material because of its excellent wind, water, and isolation qualities.

15. Plastic

Plastic is the most used item in a construction material list nowadays. Plastic is extremely lightweight and simple to deal with and maintain. There are many various kinds of plastics in the market, and each one has unique qualities and applications with the following characteristics:

Properties

- Dimensional constancy

- Ductility Durability

- Electrical protection

- Resistance to fire

- Fixing Humidity

- Melting level

- Recycling

- Strength

- Thermal attributes

- Climate boarding

- Insulation

Applications

- Chemical defence

- Finishing

- Carpentry, outside cladding, and facade panels

- Windows

- Movable shutters

- Wall covering

- Covering the floor

- Covering the roof

- Roof integrity

- Sanitary appliances

16. Steel

Steel is a kind of iron that includes 0.1 to 1.5% cementite-based carbon. It is the component that civil engineering construction projects employ the most. We can calculate the overall weight of steel bars needed for the project’s construction once we know the unit weight of steel. There are 5 types of steel bars in a typical building construction materials list:

- TMT CRS bars

- Rolled steel members

- Hard drawn steel wire fabric

- High yield strength deformed bar

- Mild steel plain bar

Properties

- It gives the structure ductility.

- It enables the building to support huge loads.

- It improves durability and strength.

Applications

- In order to prepare columns and beams, steel bars are often employed.

- It is employed in culverts, buildings, and other structures.

- It is utilised in constructions that must support a weight.

17. Bitumen

Bitumen is a black, sticky, ductile solid or semisolid that is produced as a significant byproduct during the distillation of crude oil. Bitumen connotes a class of hydrocarbons frequently including some organic material. In its fluid state, it is known as petroleum, in its semi-fluid condition as mineral tar, and in its solid state as asphalt.

Properties

- It has the typical characteristics of being solid or semisolid, dark, and sticky.

- When heat is applied, it melts or softens.

- Its specific gravity is 1.09, and it.

- It totally dissolves in carbon disulfide, according to IV.

- In all varieties of asphalt, it serves as a binder.

- It is very chemically stable but is impacted by oil.

- It has a strong insulating resistance and a low permittivity.

Applications

- Tanks, swimming pools, urinals, and other structures are lined with it to act as a damp-proof course in walls and beneath basements.

- It is used to fill up the seams in leaking roofs because it makes an excellent expansion joint.

- It is widely utilised as a building material for roads.

- It is utilised to create construction materials that insulate heat.

- It is also used to make impermeable paints, cold-moulded bituminous polymers, and roofing felt. Asphalt is coloured with red, green, or brown pigments to create bituminous paints. These paints are appropriate for waterproof and attractive flooring.

Conclusion

A good design can only be achieved with high-quality materials, therefore materials are the key to a well-functioning structure. The construction materials name list with pictures in this article has a significant impact on the building’s quality. The building materials you choose will determine the structure’s overall sturdiness, longevity, and charm. As a result, while choosing building materials, one should be meticulous.