Property Geek

We provide the actual and accurate information with unbiased user driven reviews to our viewers, to help them see the best and find the best!

View posts

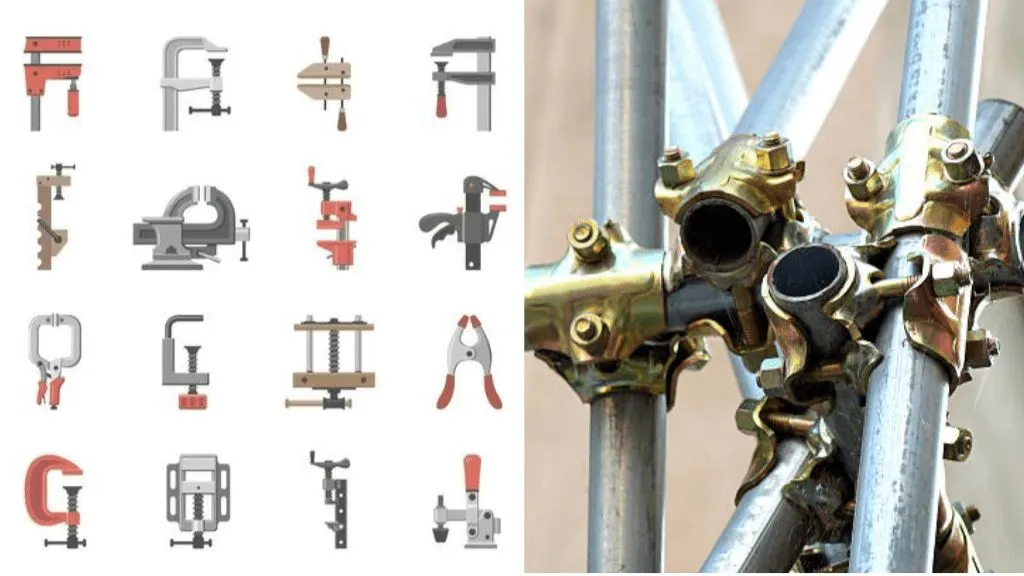

Clamps are essential tools in woodworking, metalworking, and construction, used to hold objects firmly in place during tasks like cutting, gluing, or assembling. With a wide variety of clamps available, each designed for specific applications, selecting the right one can significantly impact the efficiency and precision of your work.

Whether you’re a professional or a DIY enthusiast, understanding the different types of clamps is crucial. In this article, we’ll explore the various types of clamps, their features, and their practical uses to help you choose the perfect tool for your projects.

Listed below are the various types of clamps with their application.

These are tools that are operated by hand and are used to hold or position the workpieces when assembling or undergoing a manufacturing process. The key specifications include a few intended applications like the type of clamp or the grip range along with their features.

These hand clamps are mostly available in a very wide variety of options including a bar, parallel, draw, and toggle used for various applications; book-binding, door marking, picture framing, or certain other manufacturing operations. These are mostly used in laboratory glassware too.

These type sof clamping devices are referred to as clamping tools that are widely used to specially hold heavy material, usually lifted or manipulated. Here, the key specifications of these kinds of tools include intended applications such as the orientation of the clamping action and load capacity.

Material Handling Clamp tools are mostly used in construction applications for lifting or manipulating huge loads. Lifting heavy loads include rails, pipes, girders, etc and are also used in foundries and factories.

These are devices that are used to hold tubes or hoses in place on the ends of pipe spuds. Their specifications include the type of clamp, material, and diameter and are also named hose clamps that are used where a flexible fluid connection is to be made.

Best used for water pumps of the auto engine and the inlet spud in a radiator. Mechanical Clamps are made in various materials and sizes that include metal or plastic, depending on the application, designed for single-use or reusable devices.

These are mechanical devices that are used to secure or hang pipes with specifications including the applications of pipe diameter and clamp type. These are commonly used in plumbing and piping applications for hanging different types of pipes.

Pipe Clamps can also be used for exhaust pipes, conduits and guard rails amongst others. There are also various styles and sizes in the market for these devices including different materials depending upon the type of pipe needed to be hung.

C-Clamp types are quite popular and are the standard go-to clamp for multiple kinds of jobs. The best part of these is its simplicity and availability that are unmatched and most of the types of clamps collection begins with a few sizes of these clamps.

There are various designs that are available for various types of job requirements, these include standard c-clamps ( the most popularly known clamp), double anvil c-clamp best for distribution of even load, quick release clamps that for fast action, copper coated clamps preventing the build-up of weld spatter, and deep reach clamps for long reach.

These are referred to as the mechanical devices that are used for working grounding wires, pipes, rods, antennas, etc., including the others used for some specific tasks like refuelling an aircraft and welding.

The specifications of these include the material and the intended application. There are multiple kinds of ground clamps that are available as per the construction of the ground wire.

These F- clamps are like mechanical devices that are specially designed for a wide opening capacity. They are found to have a sliding bar, allowing the opening capacity to be adjusted easily to satisfy a wide application range.

F clamps are very popular and are best used when the c-clamp’s opening capacity is too small.

Or as also known as the quick action clamps are the most popular kind of clamps that are used in today’s market. They are best used to to tighten by the application of one hand by pumping the push handle. Quick Action Clamps are quite similar to the F – clamps wherein the opening of the clamp’s capacity is varied.

These are best used for certain job kinds, such as speeding the work, woodworking, and single handling.

These types of clamps are mechanical devices that are used to tighten spaces around a pipe or near any other surface. Its chain is put into use for a variety of shapes, such as wraps around the object to apply pressure whenever tightened.

These kinds are ideally used for jobs like metal working, one-handed, and speeding the work.

These kinds of clamps are best used to work just like the locking kind of clamps. The only difference is its availability in large surface areas in the clamp jaws and are responsible for making them ideal for clamping sheet metal works or anything similar.

These are ideal for sheet metal, metal working, one-handed, and speed work.

Kant- twist clamps are the mostly used and ideal clamps for many machine shops and welders, responsible for delivering loads with the help of two parallel clamps, also preventing the jaws from walking. As for the position of the handle, it is to be kept perpendicular with respect to the clamp load and to also prevent the clamp from twisting while tightened.

These are ideally used for jobs like; welding, metal working, woodworking, and machining.

These wood hand clamps are one of the traditional woodworking clamps with pivot jaws that allow the clamp to move at varying angles.

Wood Hand Screw clamps are ideal for jobs like wood working.

Spring Clamps are the fastest and most affordable mechanical devices. They are ones that deliver little clamp load with a very limited opening capacity and are responsible for holding down a tarp and also prevent the movement in one axis which does not have any load.

They are best used for woodworking, speeding the work, and are truly affordable.

These are mechanical devices that are quite similar to parallel clamps. They are best used for woodworking, and large assemblies.

Bench clamps are clamps that are used to screw down into a work table. These kinds allow quicker assembly clamping and are ideally used over a wooden table through the attachment accessories.

Bench clamps are best used for assembling, welding, and woodworking.

We hope the blog post above has helped you be aware of the various types of clamps with their specific uses. Make sure you choose the right kind for the right work to ease most of the process out.