Simply put, welding is the process of joining two pieces of metal together. But is that it? There goes a lot behind the process of welding, and also there are various types of welding, each with different applications.

So get your welding gear on, as we delve into the process of welding and discuss the different types of welding.

What Is Welding?

Before we deal with the different types of welding, let us first get to the basics of welding. So, what is welding?

Welding is a manufacturing method that involves fusing two or more pieces together using heat, pressure, or both to produce a joint while the parts cool. Welding is most commonly associated with metals and thermoplastics. However, it may also be used on wood.

The shipbuilding, automotive, and aerospace sectors, as well as the steel and construction industries, are the most predominant areas where welding is used.

Welding: The Process

A parent material refers to the pieces that are linked together. A filler metal, on the other hand, is usually melted into the seam of the welding, or weld. This can be done in two ways:

- Wire feeder through the welding gun (for gas metal arc welding)

- Manual-feed welding electrode

It is to be noted that the filler metal must have a melting point that is close to that of the welded substance.

Metal is melted to bridge the pieces to be linked in the welding process so that when the weld metal solidifies, the components become one. To form a weld, pressure is frequently used, sometimes in combination with heat.

Different Types Of Welding

Now the question is how many types of welding are there? Well, there are various types of welding depending on the sources of welding. The five most popular types of welding are:

- Electron Beam And Laser Welding

- Gas Metal Arc Welding (MIG Welding)

- Gas Tungsten Arc Welding (TIG Welding)

- Plasma Arc Welding

- Shielded Metal Arc Welding (Stick Welding)

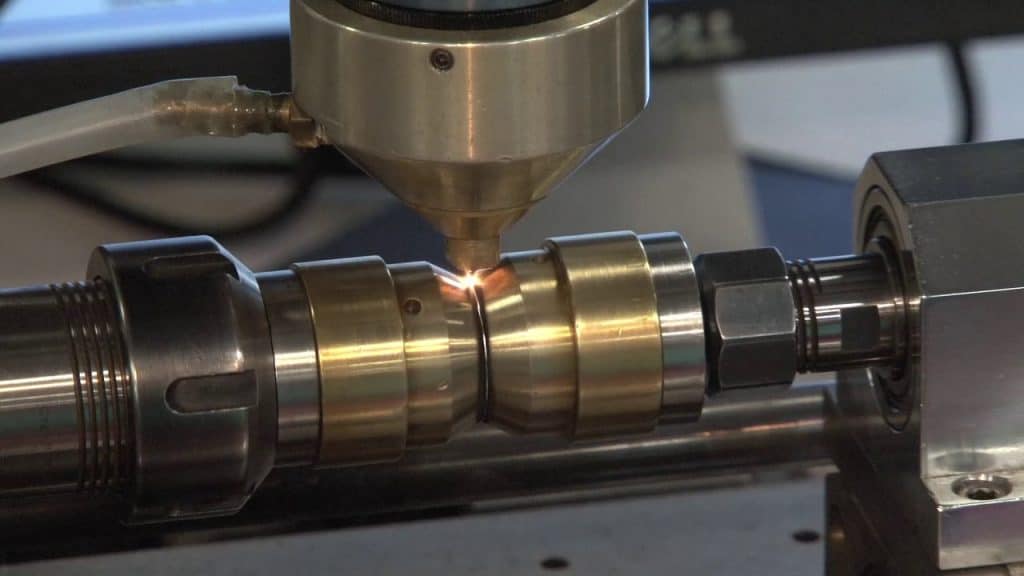

1. Electron Beam And Laser Welding

Electron beam, as well as laser welding, include very high energy-consuming welding processes that are exceedingly accurate. The focus and direction of the electron beams and lasers have the potential to be manipulated as per needs. For instance, it can be made extremely precise to weld the tiniest implanted medical devices, and at the same time deliver massive power to weld enormous spaceship components.

Welding using an electron beam or a laser is a diverse, powerful, and automatable method. From a metallurgical and aesthetic standpoint, both may produce stunning welds.

Application

- Medical equipment

- Aerospace components

2. Gas Metal Arc Welding (MIG Welding)

Gas metal arc welding or MIG welding is utilized in the automotive sector to repair automobile exhaust systems, as well as in the construction of homes and structures. It is one of the most commonly used welding techniques.

Gas metal arc welding is a form of arc welding that employs the use of an electrode, which is a wire. You’ll also employ a shielding gas to prevent contamination as it passes through the welding gun.

Application

- Automobile

- Construction

3. Gas Tungsten Arc Welding (TIG Welding)

Gas tungsten arc welding or TIG welding, in short, is a diverse welding process, and also one of the most difficult welding procedures to master.

TIG welding necessitates the use of two hands. The rod is fed with one hand while the TIG flame is held with the other. Most typical metals, such as cobalt, steel, titanium, copper alloys, aluminum, and nickel alloys, may be welded with the heat and arc created by this torch.

Bronze, magnesium, chromoly, brass, nickel alloys, stainless steel, copper, aluminum, steel, and even gold may all be welded with TIG welders.

Application

- Bike frames

- Doorknobs

- Fenders

- Lawnmowers

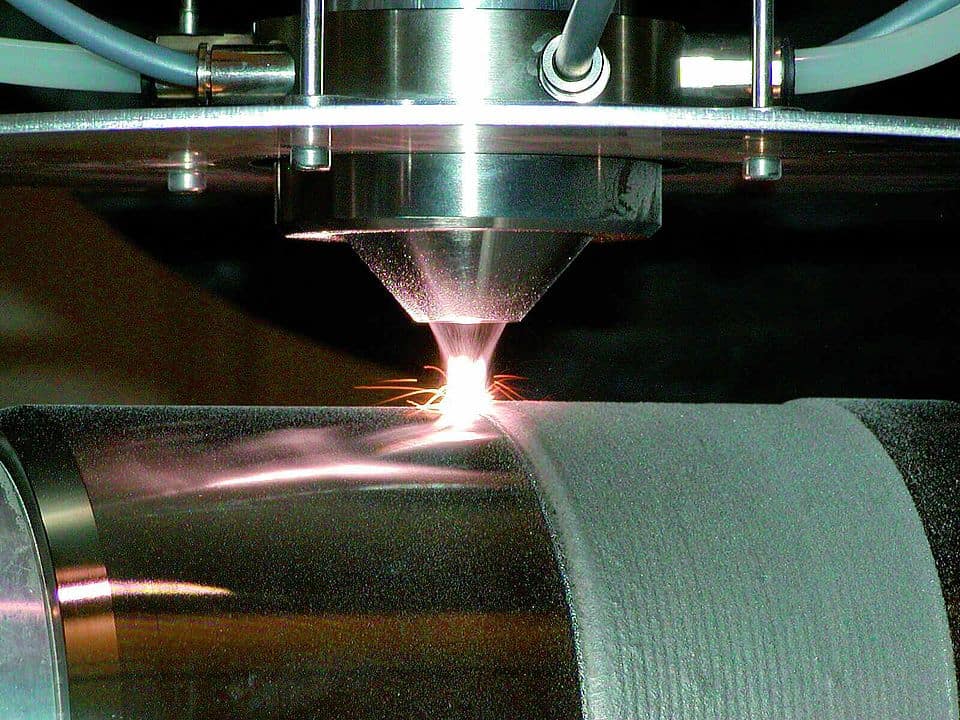

4. Plasma-Transferred Arc Welding

Plasma-transferred arc (PTA) welding is a thermal process for applying layers that are resistant to wear and corrosion on surfaces of metallic materials. It is a welding process of depositing high-quality fused deposits on comparatively cheaper surfaces.

This type of welding is similar to TIG welding in that the electrode is recessed and heat is generated by ionizing gases inside the arc. The typical gas mixture is argon for the plasma gas and argon, along with 2 to 5% hydrogen for the shielding gas. Helium can be used as a plasma gas, however, because it is hotter, it lowers the nozzle’s current rating.

Application

- Piping components

- Drilling tools

5. Shielded Metal Arc Welding (Stick Welding) :

One of the most popular types of welding is shielded metal arc welding, also called stick welding. And what makes it so special is its portability.

Construction, maintenance, and repair, as well as undersea pipelines and industrial manufacturing, all require stick welding.

By creating an arc between a covered metal electrode and the base metal workpiece, the stick softens and mixes metals. The stick’s protective layer melts as it melts, shielding the weld region from oxygen and other gases in the air.

Application

- Maintenance and repair

- Construction

- Industrial manufacturing

- Underwater pipes

Final Thought:

Welding, an important part of the construction sector, has several risks associated with it.

The process of welding produces a lot of intense light and UV radiation, which can harm your eyes. Molten metal splashes and sparks can burn the skin and constitute a fire hazard, while welding fumes can be hazardous if ingested.

It is thus advised to take precautions when carrying out welding and using appropriate welding gears.

Different Types Of Welding FAQs:

1. What is welding?

Welding is a manufacturing method that involves fusing two or more pieces together using heat, pressure, or both to produce a joint while the parts cool. Welding is most commonly associated with metals and thermoplastics.

2. How many types of welding are there?

There are different types of welding depending on the sources of welding. The five most popular types of welding are:

1. Electron Beam And Laser Welding

2. Gas Metal Arc Welding (MIG Welding)

3. Gas Tungsten Arc Welding (TIG Welding)

4. Plasma Arc Welding

5. Shielded Metal Arc Welding (Stick Welding)

3. Which is the most popular type of welding?

Gas metal arc welding or MIG welding is utilized in the automotive sector to repair automobile exhaust systems, as well as in the construction of homes and structures. It is one of the most commonly used welding techniques.