A drill is one of the most useful workshop tools, and it’s necessary for practically every job. Technically speaking, drill bits are cutting tools that are used to create a hole or expand holes in solid materials.

However, you won’t be able to utilize any drill unless you know which drill is best for your job. Drill bits are available in a wide range of diameters. Step drill bits may be used to create any surface (according to thickness).

Uses Of Various Drill Bit Types

Drill bits are used to make holes in a range of different materials. Different varieties of wood, metal, plastic, ceramic tile, porcelain, and concrete are among them. Steel, aluminum, copper, cast iron, sheet metal, fiberglass, brick, vinyl flooring, and other materials are all available as drill bits.

Drill bits are made in a variety of types to aid with various jobs and are sized for their diameter.

Materials Used For Various Drill Bit Types

The following are the materials used to make twist drills:

- High-speed steel or carbon steel is the perfect material to be used for one-piece construction.

- The cutting section is made of high-speed steel in a two-piece design.

- Carbon steel with a minimum tensile strength of 70 kilograms per square millimeter for the shank part.

Because of their higher cutting efficiency, high-speed drills are increasingly extensively employed. In addition, drills with cemented carbide-tipped tips are used in mass manufacturing.

Different Types Of Drill Bits

- Auger drill

- Brad and Pilot Point Bit

- Centre drill

- Countersinking drill

- Counter boring drill

- Double fluted drill

- Flat drill

- Forstner bit

- Glass bit

- Hammer bit

- Hole saw

- Installer bit

- Masonry Drill

- Multi-fluted drill

- Oil hole or tube drill

- Plug cutters

- Rivet Drill

- Screwdriver Drill Bit

- Shell drill

- Spade Drill Bit

- Step drill

- Spirec drill

- Straight fluted drill

- Twist drill

- Tile bits

Let’s take a look at each of these different types of drill bits for metal, woodwork, and other uses.

1. Auger Drill

- Best suited for woodwork and construction projects

- The screw-tip aids in drawing the drill; thus less pressure is required

2. Brad and Pilot Point Bit

- Can be used in woodwork

- Useful for making furniture, cabinets, and other general carpentry

- Clean exit aperture is produced by a central point in the shape of a W

- A handy tool when it comes to DIY projects

3. Centre Drill

A combination drill is another name for a center drill. It has cutting points on either of its ends and is simple in the center. With this drill, both drilling and countersinking may be done at the same time.

- Used to connect long jobs from one center to another on lathe machines

- Also used to drill the center of a rod

4. Countersinking Drill

Countersinking is executed by drilling holes where counter head screws will be placed. The head job of the screw fits well in this manner. This is a four-fluted drill with a cutting point at 60° or 82°.

- Can be used for cabinets and general woodworking

- Drills pilot holes, as well as other holes, to the proper depth.

- Creates a groove for countersinking fastener heads

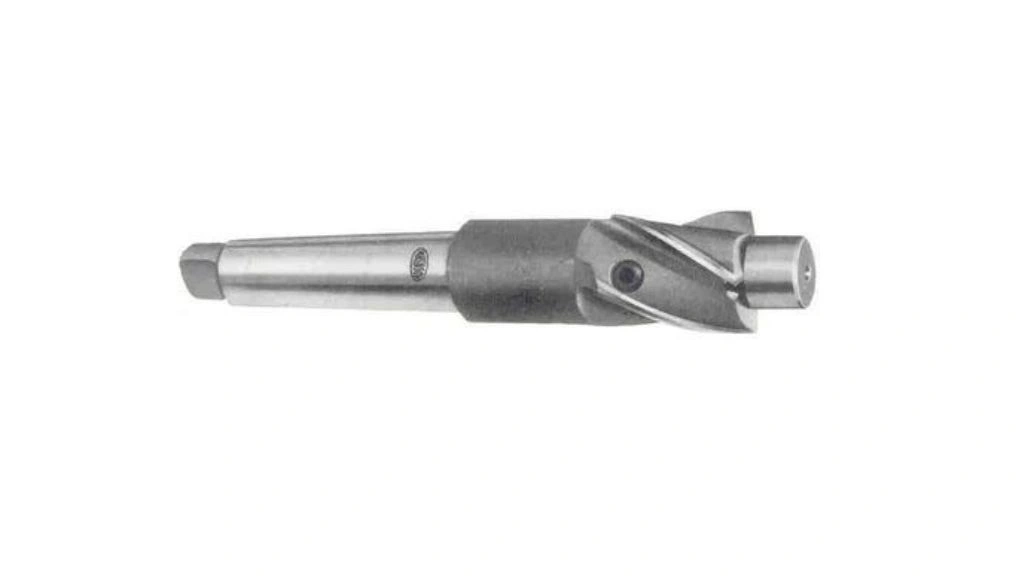

5. Counter Boring Drill

A counter boring drill is pretty much the same drill bit type but is used to make the hole bigger. These holes are bored from the top to the screw head’s height.

The work surface stays close to the plain surface while installing this type of screw. The heads of the screws do not obstruct their operation in any way and the hole is created deeper in the increasing size up to the height of the screw head.

6. Double Fluted Drill

The double fluted drill is among the most powerful drill bit types available. This type of drill bit has two flutes that are cut opposite to one another.

A double fluted drill can be used in practically every field of work.

7. Flat Drill

A flat drill is one of the various types of drill bits for metal and wood. Drills of this sort are often made of high-carbon steel. The cutting edge is ground, toughened, and hardened before being used. Flat drills are really inexpensive.

- Commonly used to bore holes in soft metals and woodwork

- The cutting point is maintained at a 90-degree angle

- After the drill bit has been hardened and tempered, it may be used on solid metals.

8. Forstner Bit

If you want to drill holes in wood that are clean and smooth, the Forstner is the perfect type of drill bit for you. This bit provides for precise hole cutting. It features a sharp tip that aids in keeping the bit exactly where you want it.

It does not have a flute and must be taken out on a regular basis to be cleaned of dust and chips.

9. Glass Bit

The glass bit is specially designed to be used on ceramic and non-tempered glass. If you’re into at-home DIY projects, the glass drill bit is a must-have! Because apart from non-tempered glass it can also be used on-

10. Hammer Bit

A hammer bit is often used to drill a perfect hole in a concrete slab, bricks, masonry, or rocks.

11. Hole Saw

If you need to install door hardware or make a wire pass-through, this is the drill bit to utilize. The hole saw forms a worthless plug, which is pushed out via a side cut-through in the saw cylinder.

You may also center the hole using an attachment and steady the blade with a pilot bit. Instead of a pilot bit, small hole saws have a built-in shank. The bi-metal hole saw is one of the types of drill bits for metal as well as wood.

12. Installer Bit

Need a drill bit for cabinetry and woodwork? The installer bit might be the best choice for you. It is used to produce wood plugs for concealing countersunk fasteners.

13. Masonry Drill

Masonry drill bits are employed in the construction of brick, stone, and concrete structures.

If you drill through concrete for an extended period of time, the tip will melt and you’ll have to replace them every time they wear out. You may also minimize this issue by removing the drill from the concrete on a regular basis.

- Concrete, brick, and masonry may all be drilled using masonry drill bits.

- It’s great for house construction and repairs.

- It’s best to use a hammer drill; certain kinds are built to work with a rotary drill, but they’re less effective.

14. Multi-Fluted Drill

The multi-fluted drill is used for a variety of tasks. This drill contains more than two flutes.

Its most defining characteristic is that the hole is drilled swiftly and cleanly due to its larger cutting edge.

15. Oil Hole Or Tube Drill

When boring a hole with a drill, coolant or lubrication is required to guarantee that the drill tip does not lose its cutting capacity after being heated.

Other drills, in addition to standard drills, include a hole drilled from the shank to the cutting point to provide lubrication up to the tooltip.

16. Plug Cutters

Among all other drill bit types, you’ll need this type of drill bit if you wish to put a wooden plug together or drill a hole in the wood. The plug cutter will help you achieve a woodworking finish that is of expert quality.

17. Rivet Drill

Another type of drill bit for metal is the rivet drill.

- Primarily for drilling small rivets into thin sheet metal

18. Screwdriver Drill Bit

- Depending on the tip type, screwdriver drill bits may be utilized with a variety of materials

- It’s great for remodeling, construction jobs, and machine work

- Used with handheld drills and impact drivers

19. Shell Drill

This isn’t your typical drill. A face cutter is employed in milling operations because of its form, which is similar to that of aside.

It is made up of four flutes. It has a one-third inch per foot taper in the upper section. It cannot be used without a mandrel.

- Used to widen a hole

20. Spade Drill Bit

- Wood may be drilled using spade drill bits

- Drilling holes in wall studs for framing, electrical, plumbing, and fine carpentry applications are all possible with this tool.

- Creates large-diameter holes.

21. Step Drill

A step drill is among the different types of drill bits for metal sheet drilling. It has the appearance of a falling ladder. Their working procedure, on the other hand, is a little more expensive than other drill bits, so if you work with sheet metal frequently, this is what you need.

You can drill holes of various sizes with a step drill bit. Another great feature of these bits is that they create de-burr holes, allowing you to clear out the debris.

22. Spirec Drill

The spirec drills are extremely sensitive. These are used to bore very small holes in spray pump nozzles, storage nipples, and other small parts. They come in a variety of sizes, ranging from 0.008 inches to 0.098 inches.

23. Straight Fluted Drill

The grooves or flutes of a straight fluted drill correspond to the drill axis. This type of drill bit may be thought of as a zero-rake cutting instrument.

- Mostly used to drill copper, brass, and other softer metals.

- When drilling brass, the twist outpaces the drill feed, causing the drill to dig into the metal.

24. Twist Drill

Twist drills are now often used to bore holes rapidly, smoothly, and with high precision. Thin alloy steel rods and high-speed steel are typically used in the making of twist drills.

- Plastic, lightweight metal, ceramics, masonry as well as wood can be drilled

- Useful for house repairs, maintenance, and construction tasks

Most popular drill bits for home usage; general-purpose rotary drilling

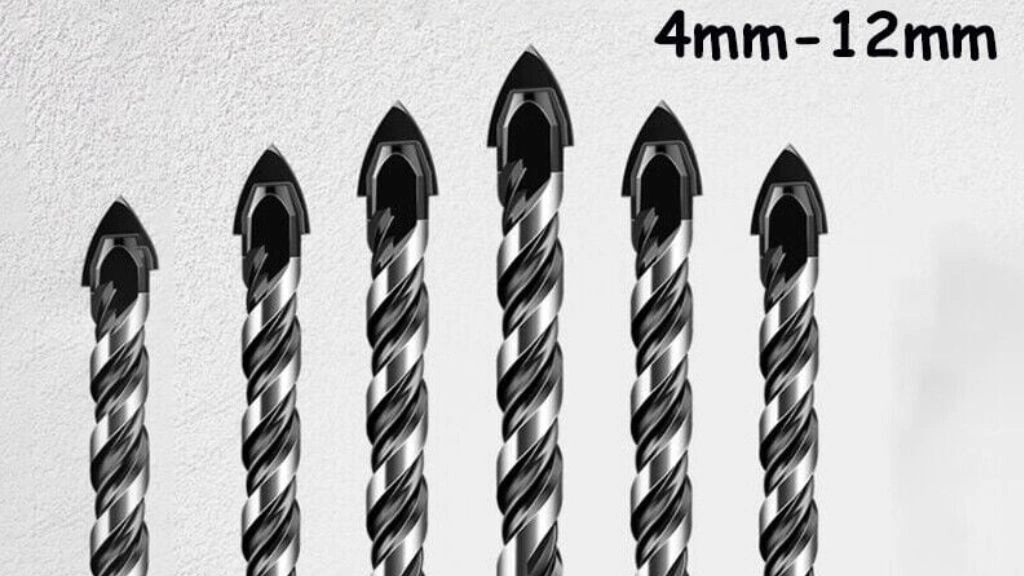

25. Tile Bits

- Porcelain and ceramic tile may both be drilled using tile drill bits

- Installing or renovating the flooring, backsplashes, and tile walls

- A carbide-tipped bit eliminates chips and fractures on tiles

Final Word: Maintenance Of Various Drill Bit Types

Drill bit maintenance is similar to tool maintenance in that it helps extend the life of your drill bits and maintains them ready for the next project.

- After you’ve done your job, let the drill bit rest so that it cools down.

- Using a cleaning cloth, wipe the drill and drill bit.

- Brush away any chips or other material that may have clung to the instrument with a dry toothbrush.

- Using a microfiber cloth or paper towel, lightly apply machine oil. Allow it to settle for a few minutes before wiping away any remaining oil with a fresh paper towel.

- Examine the drill bits for any significant damage and remove any damaged drill bits from the set so that they may be replaced.

- Return drill bits to their cases and store them in a cool, dry location.

Drill Bit Types FAQs:

1. What are the main types of drill bits?

1. Auger drill

2. Brad and Pilot Point Bit

3. Centre drill

4. Countersinking drill

5. Counter boring drill

6. Double fluted drill

7. Flat drill

8. Forstner bit

9. Glass bit

10. Hammer bit

11. Hole saw

12. Installer bit

13. Masonry Drill

14. Multi-fluted drill

15. Oil hole or tube drill

16. Plug cutters 1

7. Rivet Drill

18. Screwdriver Drill Bit

19. Shell drill

20. Spade Drill Bit

21. Step drill

22. Spirec drill

23. Straight fluted drill

24. Twist drill

25. Tile bits

2. Which are the best types of drill bits for metal?

1. Flat drill

2. Hole saw

3. Rivet drill

4. Step drill

5. Straight fluted drill

6. Twist drill

3. What are the different types of drill bits for woodwork?

1. Auger drill

2. Brad and pilot point bit

3. Countersinking drill

4. Flat drill

5. Installer bit

6. Hole saw

7. Plug cutter

8. Spade drill bit