Property Geek

We provide the actual and accurate information with unbiased user driven reviews to our viewers, to help them see the best and find the best!

View posts

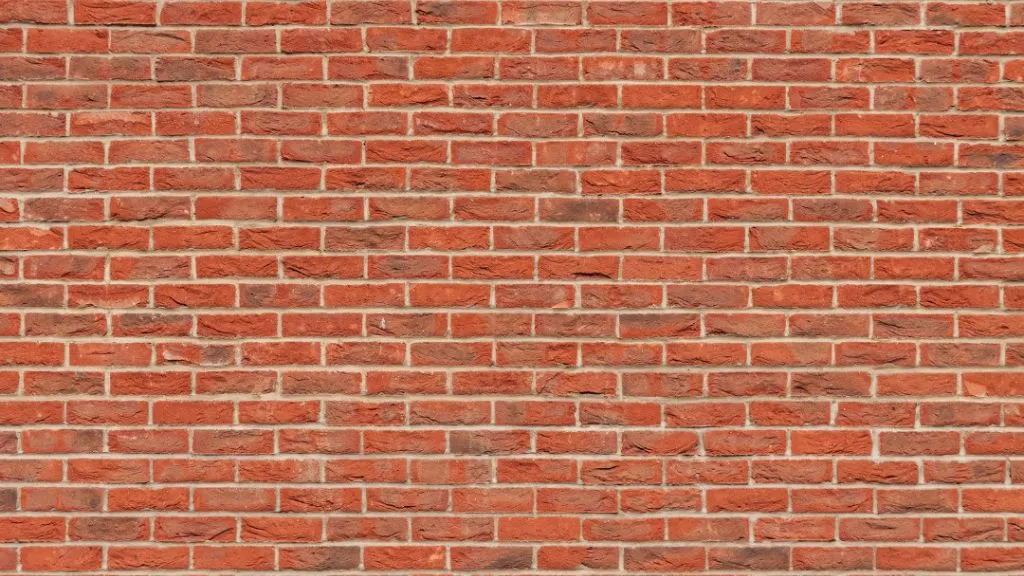

Pointing is a crucial technique in construction used to finish and seal the joints of masonry work. It not only enhances the aesthetic appeal of a structure but also protects it from weathering, water infiltration, and deterioration.

With various types of pointing available, each serves specific functional and decorative purposes, making it important to choose the right one for your project. In this article, we’ll explore the different types of pointing in construction, their techniques, and applications, ensuring durability and style in masonry work.

In building maintenance, pointing is the technique of repairing mortar joints typically between bricks and/or other masonry surfaces. The ageing mortar at times cracks and disintegrates which is when we require pointing.

The defective mortar is removed by power tool or hand and the gap is filled with fresh mortar. If possible, the new mortar is desired to be of the same composition as the original mortar. Thus, pointing can also be defined as the strengthening of stone or brick masonry joints.

Pointing does not mean simply filling up the mortar joints in masonry work. There are 8 types of pointing in construction to protect the joints from the adverse atmosphere. Deciding the type of pointing to be used on mortar joints depends on what it is protecting the joints from. Here’s a list of the different types of pointing:

Flush pointings are constructed by removing the extra mortar from the joints and making the joint flush with the face. It’s not particularly aesthetic but is durable. This type of pointing saves the joints from the accumulation of water, dust, etc.

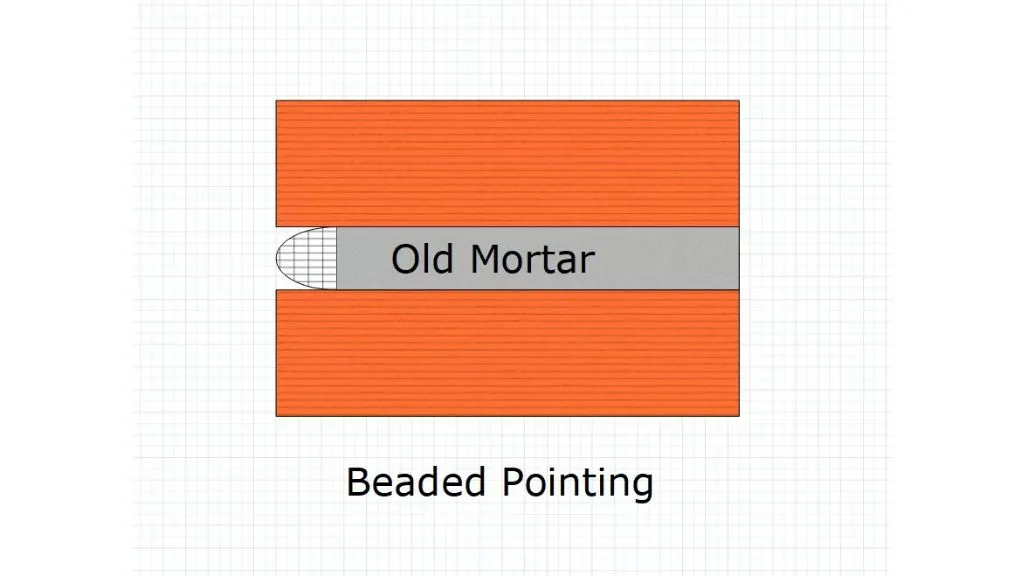

Tuck pointing is a type of pointing in construction where a groove of 3mm depth and 5 mm width is formed at the centre of the joint. This type of pointing has two types based on the projection:

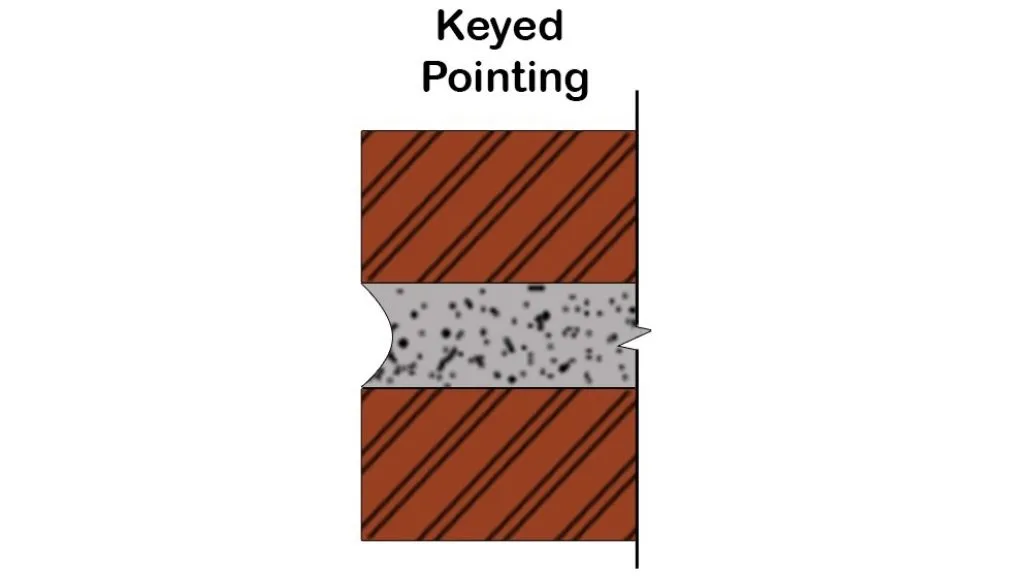

Here’s what is done while forming a keyed pointing:

Recessed pointing involves pressing the face of the pointing vertically into the wall surface with the help of a hand tool. The mortar is pressed back by 5 mm or more from its edges. Since it’s recessed, the overall appearance is great. They do not shed water so it may not be a good idea to use them for buildings exposed to water retention. This type of pointing needs to be done with bricks only so that the frost resistance is excellent.

These are formed by an iron or steel rod with concave edges. The mortar is pressed into concave grooves in the masonry joint. It does give an appealing appearance but can get damaged easily. Therefore, it needs a high maintenance routine.

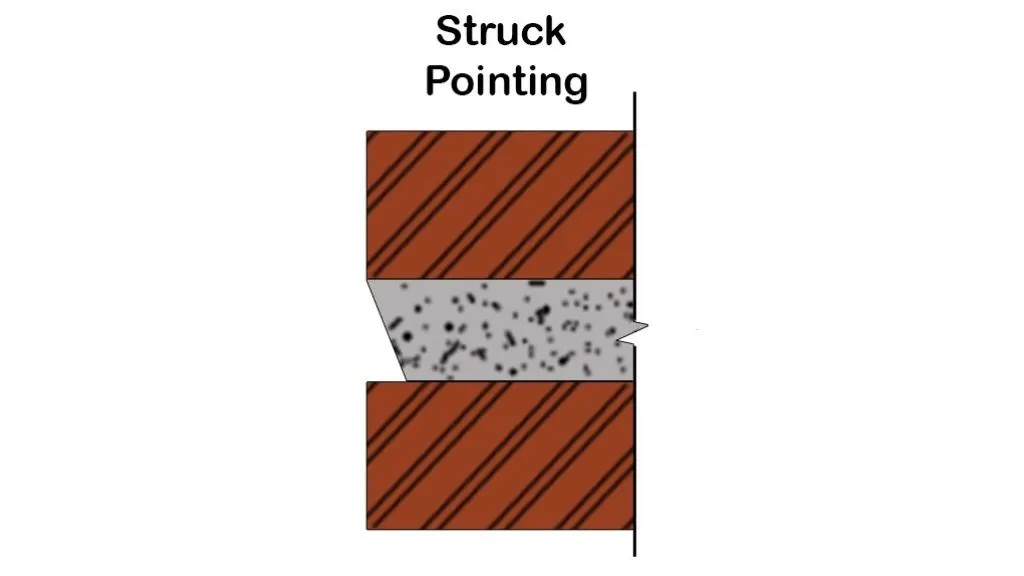

Struck pointing is done by keeping its face inclined inside the masonry while the edges are pressed into the face by 10 mm. But first, the mortar is refilled and pressed in level with the brick masonry work. Both the upper and the lower edges of the joint can be inserted into the face of the masonry but inserting the upper edge is better than the latter. It disposes water easily but with a lowered edge of the joint inside the masonry, water will easily collect. This type of pointing is called overhand struck pointing when the lower edge is inserted.

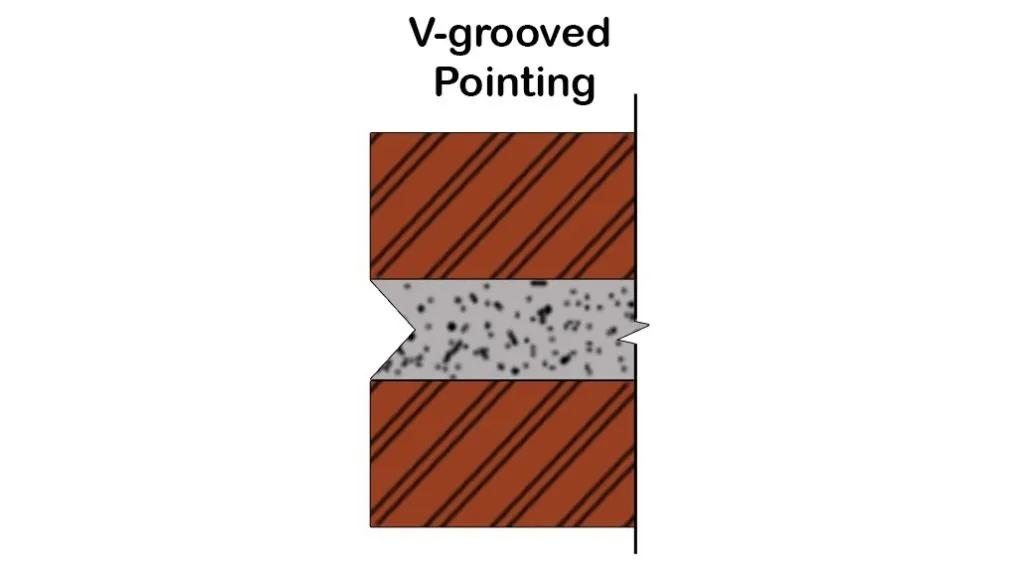

This type of pointing gets its name from the shape of the grove engraved in the flush finishing face in the mortar. They are similar to keyed pointing with the difference being the V-shaped groove. The shape is given with a V-shaped hand tool.

Also called, grooved or rubbed pointing, keyed pointing is a type of pointing where a groove is formed at its mid-height with a pointing tool such as a trowel. It is then finished off with the face of the masonry. The joint is pressed by a steel rod of 6 mm diameter and a curved arc is formed. You can even create a vertical joint in the same manner. This type of pointing gives the walls an appealing appearance.

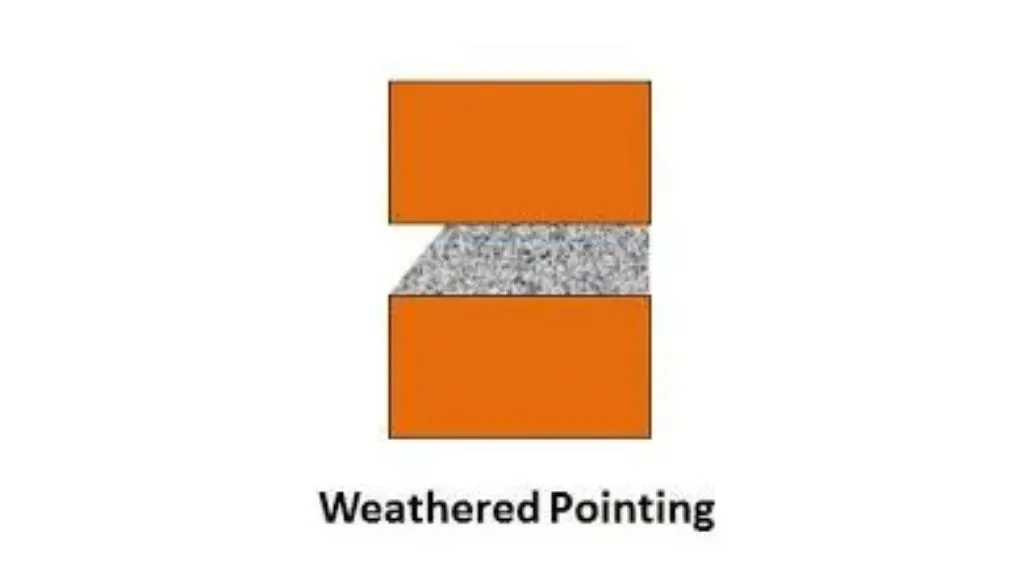

Weathered pointing also needs a V-shape in its flushing face on the mortar but the difference here is that it’s a projection and not a groove. The top of the horizontal joints of the fresh mortar is neatly pressed by 3 to 6 mm to create a projection.

All brick masonry requires pointing to maintain its condition. Restoring and keeping up the appearance of the building are the main advantages of pointing in construction. It is an essential job and a part of building maintenance. Here are some of its advantages: