Waterproofing is essential for protecting your property from the damaging effects of moisture, leaks, and dampness. Without the right materials, your home or building can suffer from mold growth, structural damage, and costly repairs.

With so many waterproofing options available, it can be challenging to choose the most effective solution for your needs. In this article, we will explore the different types of waterproofing materials, helping you make an informed decision to safeguard your property from water-related issues

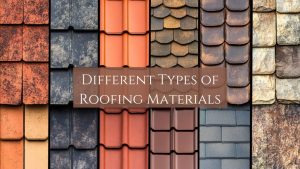

Let’s see the different types of waterproofing material.

The Top Types Of Waterproofing Techniques To Consider

But before we get into types of waterproofing substances, let’s also know where all waterproofing is needed.

Areas that require waterproofing:

- The basement of the building

- Kitchen, toilet, and bathroom

- Balcony areas

- Roof /terrace

- Swimming pool

- Water tank

Preventing the entry of water and vapor is waterproofing. Filling the structural fracture and moving is beneficial. Positive application is preferred. Different kinds of waterproofing exist. like. Bentonite, liquid, sheet membrane, and cementations. Therefore, picking the finest waterproofing technique is crucial. Some of the types of waterproofing substances are listed below.

1. Liquid Membrane for Waterproofing

By using a specialized liquid roof coating, the procedure of liquid roofing waterproofs a roof. It works well with flat, pitched, and domed roofs of various shapes and sizes. Applying a monolithic, completely bonded, liquid-based covering to a roof is known as liquid roofing. The coating hardens to create an elastic waterproof barrier that resembles rubber and can be stretched without breaking.

To offer more tensile strength, such coating systems are typically reinforced with secondary materials like glass-reinforced plastic. The majority of conventional roofing materials, including felt, asphalt, bitumen, and concrete, may be covered with coatings.

Making a new or old roof watertight may be done affordably through the technique of liquid roofing. Depending on the coating method used, it can provide performance for up to 25 years. In renovation scenarios, liquid roofing is reportedly 70% less costly than total roof replacement.

2. Waterproofing Using Polyurethane

The base and reactor are the two elements that makeup polyurethane. The base is polyol, while the reactor’s component is isocyanide. Both of them, when combined in a certain design ratio, result in a liquid coating for waterproofing purposes.

Due to its simplicity of installation, polyurethane is a very common choice. This polyurethane application requires considerably less skill and supervision than other waterproofing technologies like sheet membranes and liquid-applied membranes. This kind of treatment may be applied quickly and is also useful once construction is complete.

It is simple to apply, has a flawless finish, and is long-lasting and wear-resistant. Alkaline cleansers, battery acid, and fuels are all resistant to UV and weather.

3. Waterproofing Using Cement

The simplest waterproofing products to use are generally those made of cement. They are easily accessible from masonry product vendors, and they are simple to mix and use. A long-handled brush will simplify your life if you intend to utilize this material.

Spend the additional cash to purchase acrylic additive, a white, milky liquid that you may combine with cement. A stronger, longer-lasting coating and improved bonding will result.

The main drawback is that cementitious goods have no give, which is likely because cement doesn’t stretch in any way that’s noteworthy. They can withstand a head of water without issue, but they can hardly endure any joint or crack movement.

Cementitious waterproofing is used in the following type of structures:

- Bridges

- Dams

- Railway & Subway Systems

- Water Treatment Plants

- Sewage Treatment Plants

- Marine Cargo Ports & Docks

- Parking Structures & Lots

- Tunnels

- River Locks/Channels & Concrete Dykes

4. Bitumen Waterproofing

Systems of bituminous waterproofing are intended to safeguard both residential and commercial structures. Bitumen is a mixture of organic liquids that is extremely sticky, viscous, and waterproof (also known as asphalt or coal-tar pitch).

When building roofs, these systems, which come in the shape of roll roofing materials or roofing felt, are occasionally employed.

Using a Bituminous Membrane to Waterproof

Due to its dependable performance, bituminous membrane waterproofing is a common technique for low-sloped roofs.

A Waterproofing Technique Using Bituminous Coating

Bituminous coating is a sort of flexible protective coating that is used for waterproofing. It works well as a waterproofing and protective coating, especially on surfaces like concrete foundations.

Things to Consider Before Waterproofing

- In order to prevent water flow obstructions during the monsoon, the drains should be cleaned.

- The cause of the water leakage, whether it be a construction joint, a conduit that is leaking, a fracture in the concrete, etc., must be found and fixed right away.

- Since the integrated water approaches are current, affordable, dependable, and practical, they ought to be used throughout construction. About 1% of the cost of the structure goes towards waterproofing.

- The structure’s joints need to be planned out thoroughly and taken care of right away.

- Always seek professional advice when selecting a waterproofing system’s material, method, and contractor.

Conclusion :

In conclusion, you may inspect any section of the building’s exterior that needs waterproofing on wall, including the bathrooms and kitchen, basement, balconies, decks, green roofs, swimming pools, and water tanks, among others

As a result, you can decide which kind of waterproofing technique may be used in a certain situation. To be sure what you are doing is correct, you can also consult experts.