What Is A Cantilever Beam?

A cantilever beam is a structural element supported only at one end while the other end extends freely into space. This unique design allows it to carry loads without additional support at the free end, making it a versatile choice in building construction and engineering.

Cantilever beams are commonly used in bridges, balconies, and overhangs where unobstructed space is required. Understanding how cantilever beams work and their applications is crucial for designing efficient and innovative structures. In this article, we’ll explore the concept, uses, and advantages of cantilever beams several crucial structural activities and the fundamentals.

Who Invented Cantilevers?

Cantilevers in architecture are attributed to Frank Lloyd Wright. When Wright built the Robie House in Chicago in 1906, he employed them. The first cantilever bridge across the Main River in Germany was built in 1867, according to German engineer Gottfried Heinrich Gerber.

How Does The Cantilever Function?

Weights are supported above the beam by a cantilever. Cantilevers have no deflection because the upper half of their thickness is put under tensile tension while the lower half is under compressive stress.

A cantilever is a rigid body in which the beam is held in place by the constraints at the fixed end. The cantilever construction doesn’t move because the fixed end counteracts forces at the free end. Steel and concrete are put together to form it.

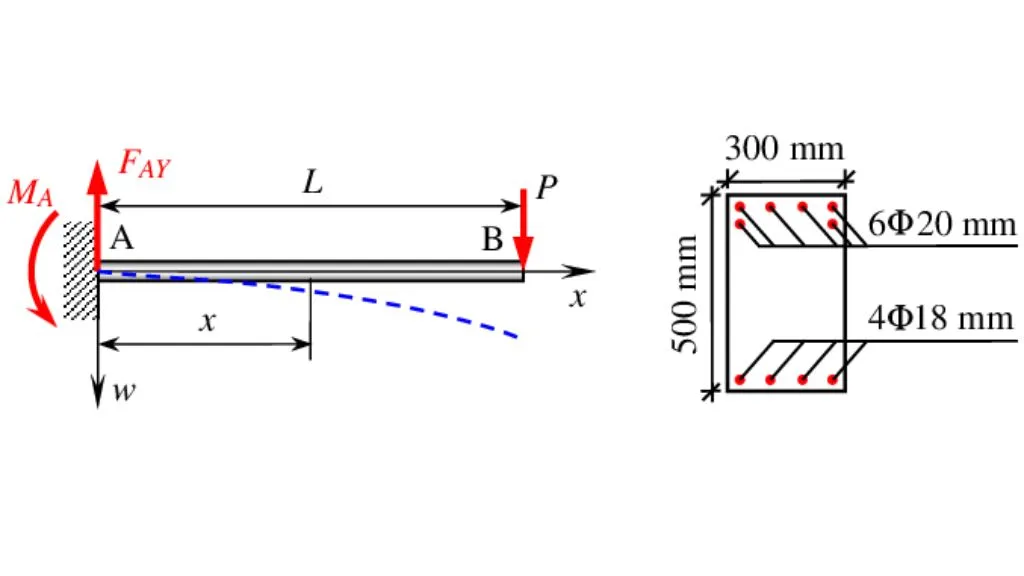

Structural Behavior Of a Cantilever Beam

A cantilever beam bends downward when it is subjected to vertical stresses. A cantilever beam can be subjected to variable load, uniform load, or point load.

Regardless of the weight, it generates an upward concavity and bends downward. This bending causes the upper fibers to be stiff and the bottom fibers to be compressed. Therefore, main reinforcement is provided to the top fiber of the concrete beam due to the significant tensile stress.

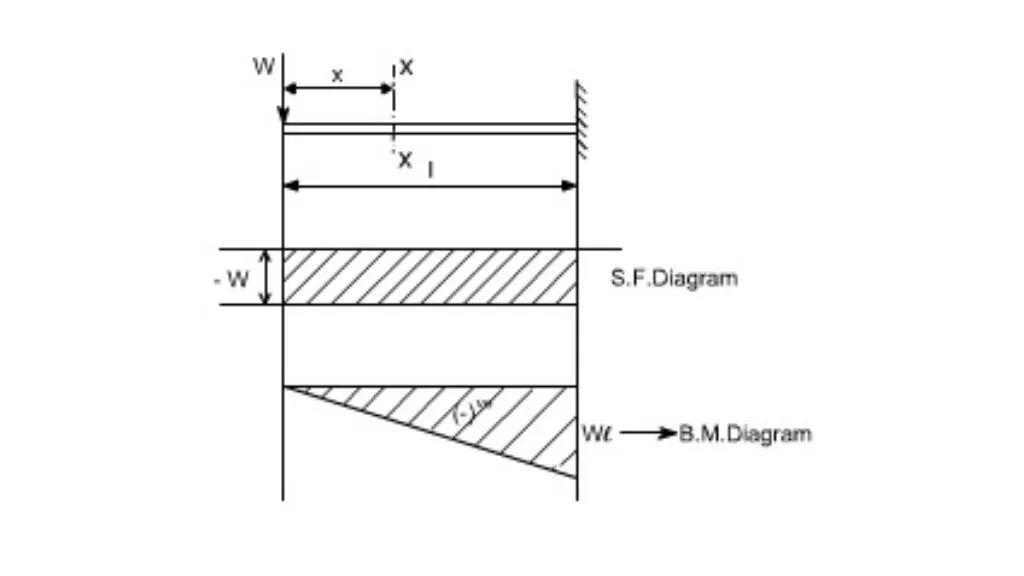

Bending Moment (BM) and Shear Force of a Cantilever Beam

The total loads between a section and the free end make up the shear force at any segment of a cantilever beam. The total of all the moments around a particular segment of a cantilever beam caused by all the loads operating between that section and the free end constitutes the bending moment at that section.

A cantilever beam’s bending moment is greatest at the fixed end and zero at the free end. For each feasible load combination, the bending and shear force diagram is calculated in order to build a cantilever beam for a construction. According to the design guidelines, a mix of dead load and live load is applied to the beam.

Design of a Cantilever Beam

Under the influence of the structural load, a cantilever beam is susceptible to moment and shear stresses. Any design approach aims to transmit these pressures to the support in a secure manner.

A cantilever beam’s bending moment ranges from zero at its free end to its greatest value at its fixed-end support. Therefore, in the design of cantilever beams, the top fiber of the concrete beam is given the primary reinforcement to safely handle the tensile stress.

A cantilever beam’s maximum span is often shaped by the following variables:

- The cantilever’s depth

- The size, kind, and placement of the load

- The standard and kind of the material utilized

Typically, the span of tiny cantilever beams is limited to 2 to 3 m. However, either by raising the depth or by adding a steel or prestressed structural unit, the span may be expanded. Given that the structure can safely convey the cantilever-generated moments to the ground, the span can be built to be rather long. The possibilities of long-spanned cantilever beams may be researched with the aid of a thorough analysis and design of the structure.

To minimize the effect of overturning, the cantilever beam must be securely fastened to the wall or support.

Also Read: Different Types of Beams Used in Construction

Cantilever Beam Applications In Construction

Applications for cantilever beam constructions include the following:

- Building balconies and cantilever beams

- Cantilever support structures for the short to medium term

- Without guy-wires free-standing radio towers

- Cantilever beam construction for pergolas

- Building lintel construction

Benefits and Drawbacks of Cantilever Beams

The following are some of cantilever beams’ key benefits:

Benefits

- Cantilever beams don’t need assistance from the other side.

- Cantilever beams’ negative bending moments serve to balance out the positive bending moments produced.

- Cantilever beams are simple to build.

Drawbacks

- Large deflections are applied to cantilever beams.

- Moments are greater for cantilever beams.

- The construction must have a sturdy fixed support or a backspan to remain stable.