Shoring is a critical construction technique used to temporarily support structures or excavations to prevent collapse during repairs, alterations, or construction activities.

This method ensures the safety of workers and the stability of the structure or site, especially in cases of weak foundations or deep excavations. Understanding the types and applications of shoring is essential for maintaining structural integrity and safety on construction sites.

In this article, we’ll explore the concept of shoring, its purpose, types, and its importance in the construction industry.

Shoring in construction is used when:

- Walls crack or bulge out due to uneven settlement of the building’s foundation

- Repairs are needed to be carried out on the cracked or bulging walls

- when an adjacent building needs to be pulled down

- When openings on walls are newly created

- When already existing openings on walls are enlarged

What is Shoring in Construction? Understand the Meaning

Shoring in construction means temporary supports that are applied to a structure or a building. A shoring system’s assembly and dismantling needs to be compliant with the decrees of Construction (Health, Safety, and Wellness) Regulations 1996. The rules made in the regulations are related to work done on buildings when there is a risk of danger or collapse to a person adjacent to or on the site.

In the Work at Height Regulations 2005, there are relevant clauses related to several risk assessments. Even though shoring is a temporary measure when more permanent supports are built, it will stay in place for a considerable time. Thus, shoring is no less significant than other elements of construction. It is to remain in place, regardless of time, and must adhere to planned safety procedures with excellent supervision during any associated assembly, and dismantling.

Why is Shoring Used in Construction?

Structural softwood is a material that is typically used for shoring members. The strength-to-weight ratio of this material is favourable when compared to that of structural steel. The adaptability of such materials is also ideal for that steel. Shoring structures can be constructed by coupling a few tubular scaffolds. The following situations request shoring in construction:

- To give some support to walls that are likely to collapse because of leaning, bulging, and subsidence.

- To prevent the collapse of sound walls due to the removal of their underlying support such as a basement being constructed near a sound wall.

- During demolition works to support adjacent structures and/or buildings.

- To give support to the upper part of the wall while drilling a large opening in the lower section of the same wall.

- To support a roof or a floor during the removal of a support wall where a beam would be constructed.

What are The Different Types of Shoring?

Each shoring system has its functionality based on a perfectly symmetrical situation. The simplest example of a shoring system would be the combination of a single figure raker, needle and cleat, soleplate, and short wall plank.

The soleplate is set at an acute angle inclination to the raker on the ground that allows the raker to be tightened with a crowbar. Then the dogs and the cleats are secured. The disposition of buildings does not always incline with the symmetrical arrangements wherever flying shored are used. Here are the different types of shoring constructions:

- Flying shoring

- Raking shoring

- Dead shoring

Let’s Check Them Out One By One!

1. Flying Shoring

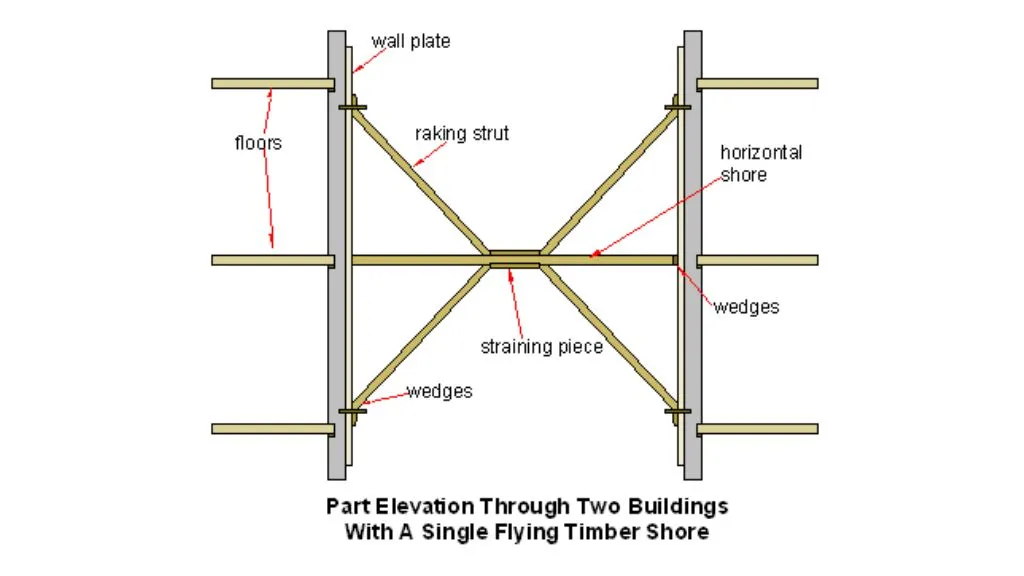

Flying shores are similar to raking shores in their funti9nanilty but the advantage of flying shore is that it provides clear working space under the shoring.

- They can be utilized in between the parallel wall surfaces if the span is limited to 12.000 m.

- Usually, short spans up to 9.000 m have a single horizontal member while larger spans need 2 horizontal shores to keep the sizes of the sections under the typical commercial timber range.

- Principle members from the smaller sections can be built with the help of all kinds of shoring construction. It is done so with the help of timber connectors and bolts and ensuring that all the butt joints are staggered perfectly to attain sturdiness.

- The site operation needed to set out and erect a flying shoring system is quite similar to that of raking shoring.

2. Raking Shoring

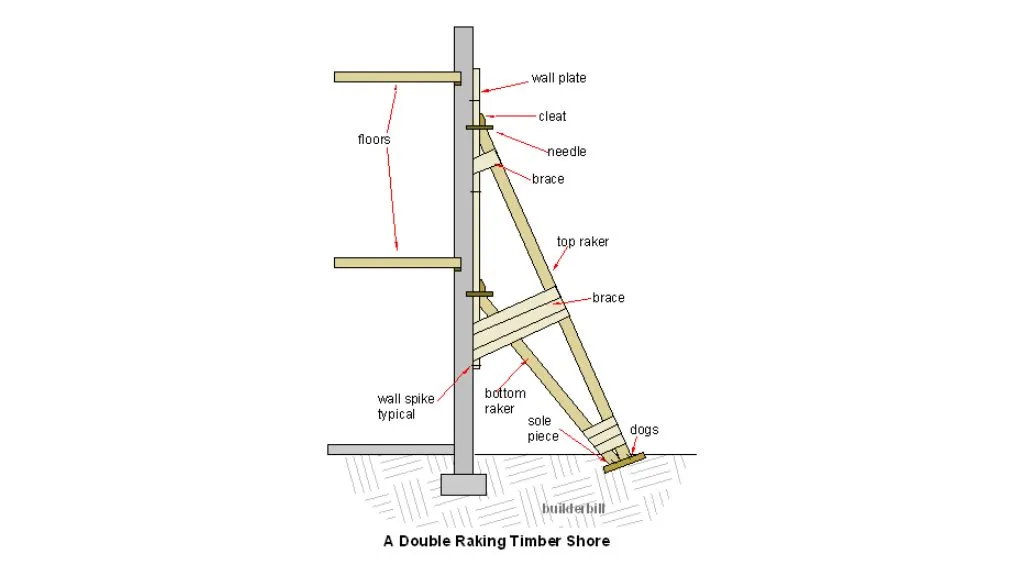

Raking is a type of shoring construction that transfers the load from walls and floors to the ground with the help of rakers of sloping struts.

- The rakers used must be correctly positioned so that they receive the maximum floor and wall loads.

- The centerline of the raker must intersect with the centerline of the floor or wall bearing.

- Every floor needs one raker inclined at an angle of 40 to 70 degrees with the horizontal. According to this calculation, the number of rakers must be 3 in number.

There is some operational sequence needed to erect a raking shore such as:

- Carrying out the investigation of the site

- Marking and cutting out the housings and mortises on a wall plate

- Setting out and cutting holes required for needles on the external wall

- Excavating for a firm bearing subsoil

- Laying soleplate and grillage platform

- Cutting and erecting rakers from the bottom shore

- A notch is cut in the heel to accommodate a crowbar to lever the raker. This tightens the shore down the soleplate. The angle between the shores and sole plate needs to be at its maximum at about 89 degrees. This ensures that the tangent point is never reached all the while making sure that the angle is not so acute that the levering becomes impractical.

- Fixing cleats, distancing blocks, cross-bracing as well as binding over the back of the shores.

3. Dead Shoring

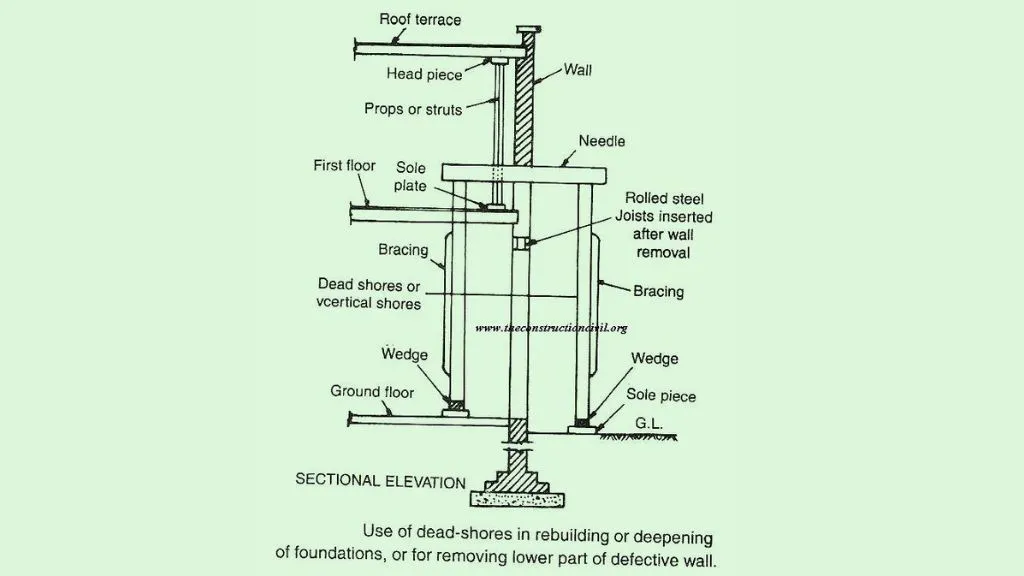

Dead shoring is a type of shoring construction that is used to support dead loads acting downwards vertically.

- In its simplest form, dead shoring consists of a shore leg or vertical prop with a sole plate, head plate, and some other means to tighten and ease the shore.

- Usually, dead shores are arranged by using 2 shore legs connected by their heads in a horizontal needle or beam.

- The dead loads are transferred by the beam or the needle down to a solid bearing surface to the shore legs.

- You might need to remove the cut holes and pavings on the suspended timber floors to reach the bearing surface.

- If there is a basement in the way, a 3rd horizontal member known as a transom might become necessary. It is impractical to manipulate a shore leg via 2 stories.

There is some sequence of operations needed to install a dead shoring construction such as:

- One needs to carry out a thorough investigation of the site to determine:

- The location of underground services that must be bridged or avoided

- The bearing capacity of floors and soil

- The number of shores needed by ascertaining possible window positions and loadings

- You need to fix the ceiling struts between the sole plates and a suitable head to relieve the wall of loads from the roof and the floor. The struts need to be positioned close to the wall.

- All the window openings near the shores need to be strutted to avoid distortion or movement. Usually, timber plates are placed against the external reveals, and then struts are placed in between them. Sometimes, the window frame may have to be removed to provide enough bearing surface for the plates.

- You need to cut slightly larger holes in the walls. They must be a bit larger than the needles.

- The floors and the ceilings also need to have holes cut in them for the short legs.

- The sleepers are positioned and leveled on a firm base. If necessary, remove the pavings.

- The shoring construction is erected, wedged, and secured.

When the shoring construction in building is completed, it is advisable to leave the shoring in the same place for at least 7 days before you start to ease the supports. This ensures that the new work has attained enough strength to self-support.

The Bottom Line: What are Scaffolding and Shoring?

The main difference between shoring and scaffolding is the main intent of the platform (deck). A scaffolding construction temporarily supports planks which the workers stand whereas a shoring construction is the vertical support of a formwork system.

Scaffolding is built alongside a structure to facilitate easy transport, transfer, or movement of equipment, materials, and workers during demolition, repair, renovation, or construction work. On the other hand, shoring is the temporary system that provides support to a structure undergoing construction, demolition, repair, or renovation.